“I'm taking a professional risk, but I'm testifying because I don't want to see a 777 and 787 crash.” It was with these words that Sam Salehpour, a quality engineer at Boeing for seventeen years, began his hearing under oath before the United States Senate. In a hearing whose title sets the tone: “Examining Boeing’s Broken Safety Culture: Eyewitness Accounts.” »

The commission heard from four engineers, employees and former employees of Boeing and the American Aviation Safety Agency (FAA), whose testimonies all point in the same direction: according to them, Boeing does not produce its planes to the standards of quality and safety required in aeronautics. Which “endangers the safety of passengers”, summarizes one of the two senators who chair the Senate commission of inquiry.

These four whistleblowers “are not the only ones to have contacted us. I invite everyone at Boeing, the FAA or the airlines to contact us,” says Senator (Democrat) Richard Blumenthal. The latter wants to hear from David Calhoun, CEO of Boeing since 2020. “He will have to explain to us why the promises to improve safety and quality made five years ago (after the two deadly 737 Max crashes in 2019 and 2019 , Editor’s note) were not kept,” he announces. As proven by the serious incident on board an Alaska Airlines flight on January 5, during which a door came loose from the fuselage of a Max 9. The investigation showed that the mounting bolts of this door, dismantled for work, had not been put back in place by Boeing workers.

“Boeing’s entire safety culture must be reviewed and restored. The nine recent audits carried out by the FAA on production and quality control methods were not good, basic defects were noted in the manufacturing of fuselages,” lists the senator, evoking a toxic culture, made of threats, pressure and hostility against employees reporting faulty workmanship. In the background are the investigations and audits now extended to both long-haul aircraft, in addition to the 737 Max. Three of Boeing's four airliners (the 767 escapes) are now in the sights of the FAA, the National Transportation Security Office and the FBI.

And Sam Salehpour drives the point home: Boeing “repeatedly” and “for three years” ignored its warnings about quality defects in the long-haul assembly process. The fuselage sections of the 787 “are not properly “attached” together and could separate in mid-flight, after having made thousands of flights,” he believes. The engineer also points to “shortcuts” in the assembly of the Dreamliner, which would have caused “deformation of the composite materials which could alter the resistance to wear in the long term”. He also cites “debris falling between parts in 80% of cases, the gaps of which are not measured correctly in 97.7% of cases”.

“I literally saw people jumping on the parts of the plane to align them,” assures the engineer, referring to the new assembly procedures for the 777, a plane put into service in 1995. These procedures were, according to him, applied, “without carrying out the necessary redesign of the parts concerned, which resulted in poor alignment between them”. Ed Pierson, former Navy and former Boeing executive, does not have harsh enough words to denounce a collective bankruptcy: of the manufacturer but also of the authorities responsible for controlling it. “The dysfunctional safety culture has not changed. Nothing was done. Anyone who boards a Boeing takes a risk,” he concludes.

Faced with these testimonies, Boeing tries to reassure. He calls these allegations “inaccurate” and reaffirms his confidence in the safety of the 787 and 777. “Jumping on airplane parts is not part of our procedures,” assures Lisa Fahl, program engineering director at Boeing Aviation. commercial. The manufacturer explains that it has carried out thousands of tests which show that the 787 and 777 meet safety criteria. However, it is proven that of the 1,123 Dreamliners delivered since 2011, those received by the companies before 2020, i.e. 939 aircraft, presented defects. The first problem identified showed greater spacing than tolerated by Boeing specifications between the edges of the fuselage sections and the straps (all of which were dismantled and checked) to connect them. “Our spacing specification is equivalent to the thickness of a human hair,” emphasizes Lisa Fahl. The discrepancy noted did not call into question flight safety, according to her.

Deliveries of the 787 were, however, suspended between November 2020 and March 2021. After the identification of new defects, deliveries of 120 aircraft were frozen from May 2021 to August 2022. “We still have 40 Dreamliners to check, in particular the joints between fuselage sections,” says Steve Chisholm, chief mechanical and structural engineer.

Concerning the integrity of the 787 fuselages, Boeing has carried out thousands of tests. Premature wear can cause cracks, called “cracking,” which can widen and ultimately threaten the structure. “We subjected the composite of the 787 fuselage to fatigue tests representing 165,000 cycles (one cycle represents takeoff, flight and landing, Editor's note), or four times more than the cycles that a 787 will perform during its lifespan. its exploitation. We found no signs of wear but on the contrary a 75% improvement in resistance compared to the aluminum used for other aircraft,” explains Steve Chisholm. As for the six-year maintenance operations (after entry into service) carried out on 671 long-haul aircraft, as well as those for the twelve years (a heavier inspection) carried out on 8 aircraft, they showed “no sign of fatigue of structure”.

The fact remains that the pressure and mistrust have gone up a notch. Boeing must very quickly show that it is changing. In February, the FAA gave it 90 days to submit an action plan aimed at resolving the quality problems. Failing this, new measures could be taken. Some observers do not rule out a total shutdown of production. A disaster scenario that Boeing still has a month to avoid…

Russia: schools will train children to use drones at the start of the school year

Russia: schools will train children to use drones at the start of the school year Austria: incestuous torturer Josef Fritzl, nicknamed the “national monster”, could soon be released

Austria: incestuous torturer Josef Fritzl, nicknamed the “national monster”, could soon be released An airline continues to treat a centenarian as a one-year-old baby

An airline continues to treat a centenarian as a one-year-old baby Germany: the trial of nine “Citizens of the Reich” conspirators begins this Monday

Germany: the trial of nine “Citizens of the Reich” conspirators begins this Monday Sánchez cancels his agenda and considers resigning: "I need to stop and reflect"

Sánchez cancels his agenda and considers resigning: "I need to stop and reflect" The Federal Committee of the PSOE interrupts the event to take to the streets with the militants

The Federal Committee of the PSOE interrupts the event to take to the streets with the militants Repsol: "We want to lead generative AI to guarantee its benefits and avoid risks"

Repsol: "We want to lead generative AI to guarantee its benefits and avoid risks" Osteoarthritis: an innovation to improve its management

Osteoarthritis: an innovation to improve its management Sanofi: demonstration in front of Paris headquarters against job cuts

Sanofi: demonstration in front of Paris headquarters against job cuts The Chinese car manufacturer BYD sets out to conquer France

The Chinese car manufacturer BYD sets out to conquer France Public finances: after the deputies, Bruno Le Maire asks the senators for savings avenues

Public finances: after the deputies, Bruno Le Maire asks the senators for savings avenues Faced with opposition from London, a fund supported by Abu Dhabi abandons the purchase of the Daily Telegraph

Faced with opposition from London, a fund supported by Abu Dhabi abandons the purchase of the Daily Telegraph Omar Sy on all cultural fronts

Omar Sy on all cultural fronts Jacques Audiard, Swann Arlaud, Benjamin Stora... A hundred men from cinema, theater and books in support of

Jacques Audiard, Swann Arlaud, Benjamin Stora... A hundred men from cinema, theater and books in support of Resale, scams and fake tickets: how not to get scammed before Taylor Swift concerts

Resale, scams and fake tickets: how not to get scammed before Taylor Swift concerts Isild Le Besco is not ready to file a complaint against Benoît Jacquot

Isild Le Besco is not ready to file a complaint against Benoît Jacquot Omoda 7, another Chinese car that could be manufactured in Spain

Omoda 7, another Chinese car that could be manufactured in Spain BYD chooses CA Auto Bank as financial partner in Spain

BYD chooses CA Auto Bank as financial partner in Spain Tesla and Baidu sign key agreement to boost development of autonomous driving

Tesla and Baidu sign key agreement to boost development of autonomous driving Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV The home mortgage firm rises 3.8% in February and the average interest moderates to 3.33%

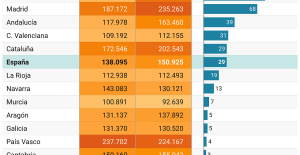

The home mortgage firm rises 3.8% in February and the average interest moderates to 3.33% This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Europeans: a senior official on the National Rally list

Europeans: a senior official on the National Rally list Blockade of Sciences Po: the right denounces a “drift”, the government charges the rebels

Blockade of Sciences Po: the right denounces a “drift”, the government charges the rebels Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Football: the CAS suspends the sanction of Gabigol who will be able to play again

Football: the CAS suspends the sanction of Gabigol who will be able to play again Wrestling: everything you need to know about the sport

Wrestling: everything you need to know about the sport Luis Enrique before Dortmund-PSG: “We must not see pressure as a threat”

Luis Enrique before Dortmund-PSG: “We must not see pressure as a threat” Tennis: the astonishing ploy of Medvedev’s coach to avoid being filmed in his box

Tennis: the astonishing ploy of Medvedev’s coach to avoid being filmed in his box