Harald Hanßen puts on his helmet and opens the door to VERA, the recycling plant for waste water treatment residues. It is perhaps the most inconspicuous building on the grounds of the Hamburg Wasser sewage treatment plant at Köhlbrandhöft, which Hanßen manages. But VERA is one of the most important building blocks in dealing with the wastewater of 2.4 million people. From mid-October it will be expanded to become the largest sewage sludge incineration plant in Germany.

Every piece of toilet paper, every leftover meal washed away in Hamburg and every liter of waste water ends up in the sewage treatment plant - and what's left after all cleaning stages, the decomposition in the big silver eggs and the subsequent drying goes to the VERA.

That's almost exactly 51,000 tons of sewage sludge per year on average - from Hamburg alone. The VERA has been in operation since 1997 and is now to be expanded and renovated. The costs will be around 200 million euros. But not only because of the planned high investment does an entire industry look to Hamburg with interest.

The reason for this is the new version of the Sewage Sludge Ordinance from 2017. With this, the federal government has imposed on the operators of larger sewage treatment plants to extract phosphorus from the sewage sludge by 2029 at the latest. For medium-sized sewage treatment plants, the deadline is 2032. By 2023, however, sewage treatment plant operators must explain to the responsible authorities how they will recover phosphorus in the future. This is not possible with the disposal methods used by many sewage treatment plants. With an incinerator like the VERA, yes.

The ordinance also restricted the possibilities of applying sewage sludge to fields as fertilizer. This leads to even more sewage sludge, for which there must be alternative disposal options. According to figures from the industry association, 571 sewage treatment plants in Germany are affected by the new regulations. Together they treat 60 percent of municipal wastewater.

But even the sewage treatment plant operators, who have not been affected so far, are preparing to change their disposal methods, as a look at the neighboring state of Schleswig-Holstein shows. According to the Ministry of Environment and Agriculture, 70 percent of the sewage sludge produced there was applied to agricultural land in 2020.

According to the country's current waste management plan, the high proportion reflects stable demand from farmers. However, "agricultural recycling cannot be classified per se as a safe disposal option". It has always been in the area of conflict between resource protection and environmental pollution. Because sewage sludge also contains metals and other substances that do not belong in farmland. Bit by bit, the legal regulations on soil protection have been tightened in recent years.

"The Fertilizer and Fertilizer Ordinance are being amended at ever shorter intervals," explains Harald Hanßen. That's why they're happy that Hamburg has long relied on incinerating the sludge. That was not always so. From the start of operation of the sewage treatment plant in 1961 until 1983, the sewage sludge was unloaded in the mouth of the Elbe. The city drainage then brought the sludge to landfills in the GDR or the then new federal states until 1997. But when the price per unloaded ton rose from 30 to 330 marks, Hamburg wanted to become independent - and planned to build the VERA.

Today, the incineration plant has three so-called lines that incinerate the sludge that has been thickened in the sewage sludge dewatering and drying plant KETA after the digestion towers, and in the process generate electricity and heat – incidentally, so much that the sewage treatment plant meets its electricity and heat requirements can not only cover itself completely, but also feeds electricity into the grid and transfers heat to the neighboring container terminal in Tollerort. In addition, VERA cleans the resulting flue gas and, among other things, recovers nine tons of gypsum per day.

A fourth line is now being built. Construction will start on October 12th. Hamburg-Wasser managing director Ingo Hannemann explains that this will not only increase the capacities in VERA, but that the expansion is also important because the three existing lines of VERA were switched off after 25 years in which they were only switched off for five whole days , need to be rehabilitated. "But that's not possible during ongoing operations," says Hannemann.

Because VERA is working to capacity – also because Hamburg is processing sludge for the surrounding community. "Only when the fourth line is finished can we successively convert two of the three existing lines," explains Hannemann. The third could also be renovated, but the entrepreneurial decision had not yet been made.

The fourth line is scheduled to go into operation in 2024. Finally, in 2027, the two existing lines two and three are to be converted and VERA will then be able to incinerate its new capacity of 76,000 tons of sewage sludge per year. However, since it is not to be expected in five years that the people of Hamburg and the industrial companies of the Hanseatic city, which also have their waste water treated in the Kohlbrandhöft, will produce so much more sludge, Hamburg Wasser has acquired new cooperation partners.

The disposal companies in Lübeck and AZV Südholstein, for their part, had been looking for companies that would take about 17,000 tons of sewage sludge from them each year. In the market investigation process that the disposal companies started, Hamburg Wasser was able to convince the most and the three disposal companies became partners and agreed on 2027 as the first year in which the 17,000 tons of sludge should be delivered.

But what the VERA cannot do even after its expansion and renovation is directly recovering phosphorus. This will take place in a special facility that extracts more than 80 percent of the phosphorus present from the ashes. Tetraphos is the name of this plant, which Hamburg Wasser built together with the waste disposal company Remondis. After a small-scale pilot project, the industrial-scale plant was put into operation at the turn of the year 2020/2021. However, it currently does not continuously release phosphorus from the sewage sludge ash. According to Hannemann, the aim is to achieve stable 24-hour operation as quickly as possible. "Since the system is so far unique in the world, this process is not working according to a formula for us either."

The phosphate is extracted from the ash as an acid and then sold on and mainly processed into fertiliser. But companies in the automotive, electroplating and chemical industries also need phosphoric acid. It is true that there are phosphate deposits in the world that would last for hundreds of years. But almost three quarters of these are concentrated in a few areas – and Germany does not want to become dependent on them.

The ash that is left over at the end can also be used: it is added as a filler in the building materials industry. Only the very last remnant of the rest still ends up in a landfill.

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump Maurizio Molinari: “the Scurati affair, a European injury”

Maurizio Molinari: “the Scurati affair, a European injury” Hamas-Israel war: US begins construction of pier in Gaza

Hamas-Israel war: US begins construction of pier in Gaza First three cases of “native” cholera confirmed in Mayotte

First three cases of “native” cholera confirmed in Mayotte Meningitis: compulsory vaccination for babies will be extended in 2025

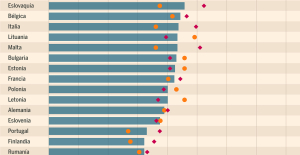

Meningitis: compulsory vaccination for babies will be extended in 2025 Spain is the country in the European Union with the most overqualified workers for their jobs

Spain is the country in the European Union with the most overqualified workers for their jobs Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Inflation rebounds in March in the United States, a few days before the Fed meeting

Inflation rebounds in March in the United States, a few days before the Fed meeting Video games: Blizzard cancels Blizzcon 2024, its annual high mass

Video games: Blizzard cancels Blizzcon 2024, its annual high mass Falling wings of the Moulin Rouge: who will pay for the repairs?

Falling wings of the Moulin Rouge: who will pay for the repairs? “You don’t sell a company like that”: Roland Lescure “annoyed” by the prospect of a sale of Biogaran

“You don’t sell a company like that”: Roland Lescure “annoyed” by the prospect of a sale of Biogaran Exhibition: in Deauville, Zao Wou-Ki, beauty in all things

Exhibition: in Deauville, Zao Wou-Ki, beauty in all things Dak’art, the most important biennial of African art, postponed due to lack of funding

Dak’art, the most important biennial of African art, postponed due to lack of funding In Deadpool and Wolverine, Ryan and Hugh Jackman explore the depths of the Marvel multiverse

In Deadpool and Wolverine, Ryan and Hugh Jackman explore the depths of the Marvel multiverse Tom Cruise returns to Paris for the filming of Mission Impossible 8

Tom Cruise returns to Paris for the filming of Mission Impossible 8 Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

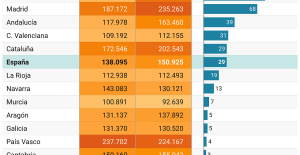

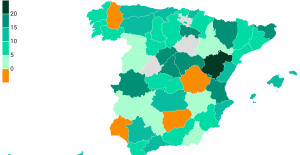

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Basketball: Strasbourg appeals the victory recovered by Monaco

Basketball: Strasbourg appeals the victory recovered by Monaco Top 14: UBB with Tatafu and Moefana against Bayonne

Top 14: UBB with Tatafu and Moefana against Bayonne MotoGP: Bagnaia dominates qualifying practice in Spain and sets track record

MotoGP: Bagnaia dominates qualifying practice in Spain and sets track record Olympic Games: in Athens, Greece transmits the Olympic flame to France

Olympic Games: in Athens, Greece transmits the Olympic flame to France