Surprise: 89 percent of the tissues with which they are clothed, the interior of the new Audi A3 is consisting of bottles in recycled PET (a thermoplastic resin) to be transformed into yarn by a process technically refined. The result? Tissues that, from the point of view of the visual and tactile, will ensure the same quality standards of the coatings classic.

In Germany and many european Countries, the empty bottles are inserted in the special automatic machines to receive, in exchange for an incentive of up to 25 cents a piece. But what happens after that? The disposable bottles are pressed and compacted to limit the overall length for transport. Once they arrived at the recycling plants, are divided according to the color, the size and quality of preservation. Separate the foreign materials, such as stoppers, a specific grinding tenderizes the bottles up to get “flakes” are intended to be washed, dried and melted.

Created a uniform mass, of the nozzles give rise to filaments without solution of continuity, after cooling, are chopped. The granulate produced in this way is transformed by extrusion into yarn, after being wound on spools, is intended for the production of the fabrics.

To make the upholstery of the seats of the new Audi A3 are required up to 45 in PET bottles of 1.5 liters. To these you add more 62 recycled bottles, destined to the carpet. The sustainability of the cockpit is further pointed out by many of the components produced making use of waste materials: for example, the inserts sound-deadening and vibration damping, floor mats and the side surfaces of the trunk.

today, however, the seat covers are not entirely of recycled materials. “The challenge is represented by the lower cloth, and attached to the upper material by means of an adhesive. We are working to replace the latter with a solution of polyester recyclable,” explains Ute Grönheim, responsible for the development of the textile materials of Audi AG. “The horizon is to produce coatings with a recycled pure, intended for further reuse so as to give life to a virtuous circle. We are not far from this goal.”

In Germany and many european Countries, the empty bottles are inserted in the special automatic machines to receive, in exchange for an incentive of up to 25 cents a piece. But what happens after that? The disposable bottles are pressed and compacted to limit the overall length for transport. Once they arrived at the recycling plants, are divided according to the color, the size and quality of preservation. Separate the foreign materials, such as stoppers, a specific grinding tenderizes the bottles up to get “flakes” are intended to be washed, dried and melted.

Created a uniform mass, of the nozzles give rise to filaments without solution of continuity, after cooling, are chopped. The granulate produced in this way is transformed by extrusion into yarn, after being wound on spools, is intended for the production of the fabrics.

To make the upholstery of the seats of the new Audi A3 are required up to 45 in PET bottles of 1.5 liters. To these you add more 62 recycled bottles, destined to the carpet. The sustainability of the cockpit is further pointed out by many of the components produced making use of waste materials: for example, the inserts sound-deadening and vibration damping, floor mats and the side surfaces of the trunk.

today, however, the seat covers are not entirely of recycled materials. “The challenge is represented by the lower cloth, and attached to the upper material by means of an adhesive. We are working to replace the latter with a solution of polyester recyclable,” explains Ute Grönheim, responsible for the development of the textile materials of Audi AG. “The horizon is to produce coatings with a recycled pure, intended for further reuse so as to give life to a virtuous circle. We are not far from this goal.”

"The Republic will fight always in defense of the freedom of information, to its readers and to all those who have at heart the principles of democracy and civil coexistence"

Carlo Verdelli SUBSCRIBERS TO REPUBLIC © Reproduction reserved Today on The Coronavirus clear Italian skies: the crisis hits the air transport The great frost of coronavirus on tourism. "Erased up to 40% of bookings" If the fear becomes a disease Together when it's convenient Coronavirus, the iron arm of the losers between the government and the Regionsthe Republic

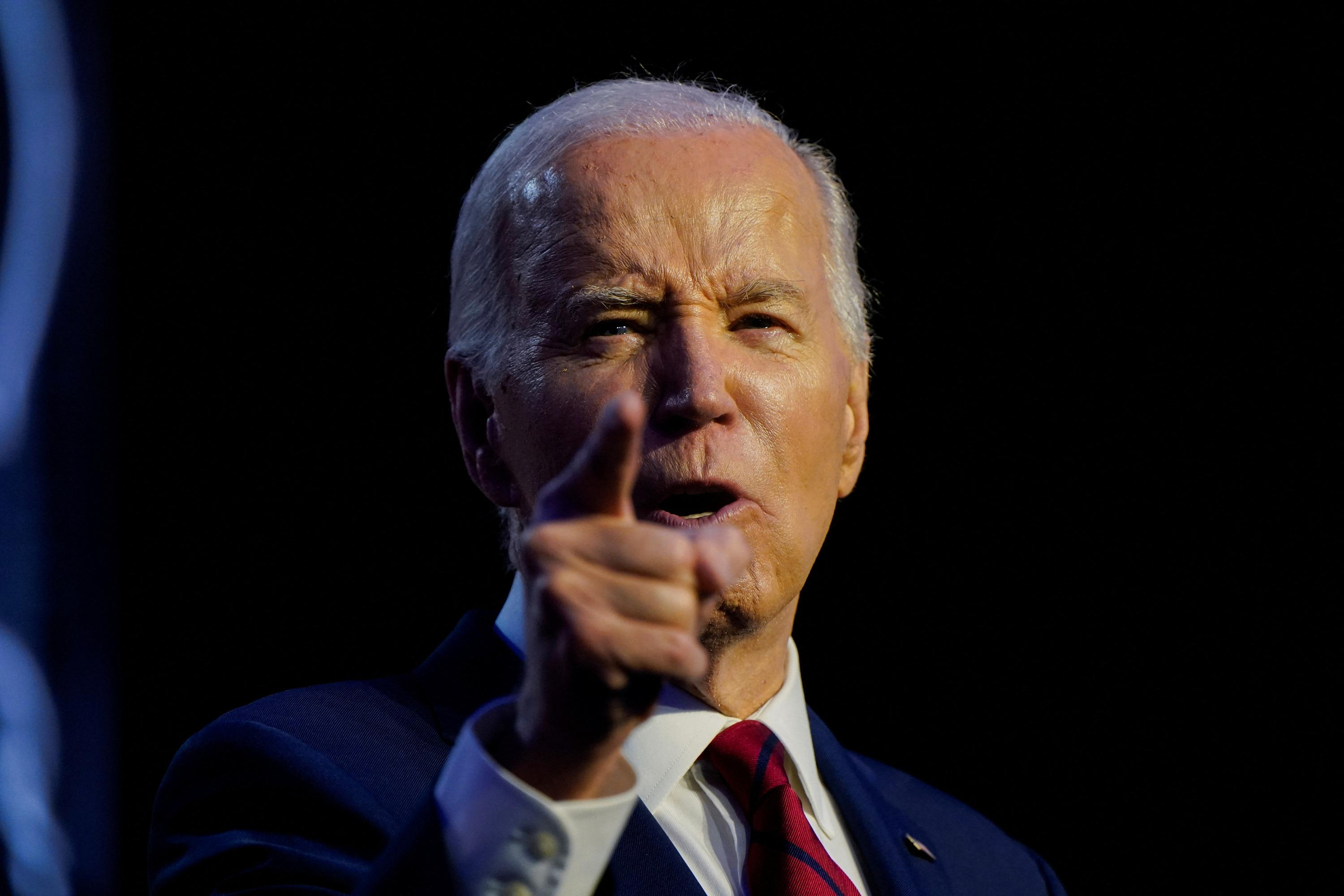

Hamas-Israel war: US begins construction of pier in Gaza

Hamas-Israel war: US begins construction of pier in Gaza Israel prepares to attack Rafah

Israel prepares to attack Rafah Indifference in European capitals, after Emmanuel Macron's speech at the Sorbonne

Indifference in European capitals, after Emmanuel Macron's speech at the Sorbonne Spain: what is Manos Limpias, the pseudo-union which denounced the wife of Pedro Sánchez?

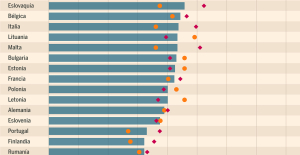

Spain: what is Manos Limpias, the pseudo-union which denounced the wife of Pedro Sánchez? Spain is the country in the European Union with the most overqualified workers for their jobs

Spain is the country in the European Union with the most overqualified workers for their jobs Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Colorectal cancer: what to watch out for in those under 50

Colorectal cancer: what to watch out for in those under 50 H5N1 virus: traces detected in pasteurized milk in the United States

H5N1 virus: traces detected in pasteurized milk in the United States Private clinics announce a strike with “total suspension” of their activities, including emergencies, from June 3 to 5

Private clinics announce a strike with “total suspension” of their activities, including emergencies, from June 3 to 5 The Lagardère group wants to accentuate “synergies” with Vivendi, its new owner

The Lagardère group wants to accentuate “synergies” with Vivendi, its new owner The iconic tennis video game “Top Spin” returns after 13 years of absence

The iconic tennis video game “Top Spin” returns after 13 years of absence Three Stellantis automobile factories shut down due to supplier strike

Three Stellantis automobile factories shut down due to supplier strike A pre-Roman necropolis discovered in Italy during archaeological excavations

A pre-Roman necropolis discovered in Italy during archaeological excavations Searches in Guadeloupe for an investigation into the memorial dedicated to the history of slavery

Searches in Guadeloupe for an investigation into the memorial dedicated to the history of slavery Aya Nakamura in Olympic form a few hours before the Flames ceremony

Aya Nakamura in Olympic form a few hours before the Flames ceremony Psychiatrist Raphaël Gaillard elected to the French Academy

Psychiatrist Raphaël Gaillard elected to the French Academy Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

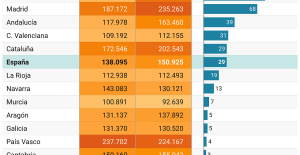

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

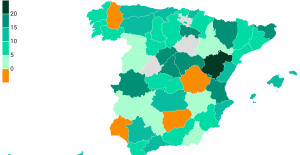

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition

With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Judo: Blandine Pont European vice-champion

Judo: Blandine Pont European vice-champion Swimming: World Anti-Doping Agency appoints independent prosecutor in Chinese doping case

Swimming: World Anti-Doping Agency appoints independent prosecutor in Chinese doping case Water polo: everything you need to know about this sport

Water polo: everything you need to know about this sport Judo: Cédric Revol on the 3rd step of the European podium

Judo: Cédric Revol on the 3rd step of the European podium