Regular use of metals and plastics can result in dullness in look, over time. Many of us by now have realized that regular cleaning tools have a limit to their effectiveness with regards to these materials. To restore them to their initial shine, there is a need for an ultrasonic cleaner, and to understand the process of how this machine works, one must go a step further.

Every ultrasonic cleaner function based on the process of cavitation, which is the creation of bubbles that aids the cleaning process. When choosing an ultrasonic cleaner, picking the right frequency wave suitable for the particular material is paramount. This parameter is of great importance because using the wrong frequency could lead to irreparable damage. Determining the right frequency can be complicated but generally, more sensitive materials require a higher frequency and vice versa.

The volume of the cleaning liquid better known as the bath liquid is directly proportional to the ultrasonic power. This parameter, expressed in Watts per liter, is a determinant of the level of the cleaning application. The greater the ultrasonic power, the greater the intensity of cavitation. Therefore you should aim for an ultrasonic cleaner with high ultrasonic power.

Temperature and viscosity are two factors on which the efficiency of an ultrasonic cleaner is highly dependent. Viscosity has to do with the density of a liquid and generating optimal cavitations requires minimal viscosity. This is where temperature comes into play, the higher the temperature, the lower the viscosity. In other words, an increase in temperature will cause a dense liquid to become more fluid. Temperature is the most important parameter in an ultrasonic cleaner because it not only affects viscosity and fluid pressure but also the solubility of the gas in the liquid.

This brings us to the final parameter. The quantity of gas in the cleaning liquid should be as minimal as possible. It is advisable to degas the liquid in order to ensure optimal cavitations and effective cleaning.

Once all the above-listed parameters are met, you can rest assured that the device will be of utmost efficiency. Luckily, many ultrasonic cleaners offer these benefits so finding the right one for you will not be a hassle. Be aware that the ultrasonic cleaner takes away dents and dust, it does not sterilize these materials. The ultrasonic cleaner is suitable for various metals, glass, and plastic, this device is a must-have for individuals as well as businesses.

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump Maurizio Molinari: “the Scurati affair, a European injury”

Maurizio Molinari: “the Scurati affair, a European injury” Hamas-Israel war: US begins construction of pier in Gaza

Hamas-Israel war: US begins construction of pier in Gaza First three cases of “native” cholera confirmed in Mayotte

First three cases of “native” cholera confirmed in Mayotte Meningitis: compulsory vaccination for babies will be extended in 2025

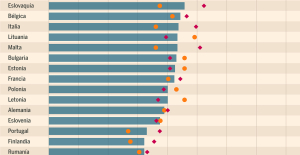

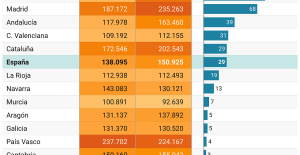

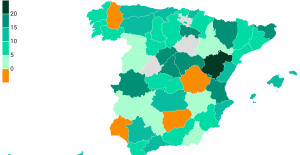

Meningitis: compulsory vaccination for babies will be extended in 2025 Spain is the country in the European Union with the most overqualified workers for their jobs

Spain is the country in the European Union with the most overqualified workers for their jobs Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Inflation rebounds in March in the United States, a few days before the Fed meeting

Inflation rebounds in March in the United States, a few days before the Fed meeting Video games: Blizzard cancels Blizzcon 2024, its annual high mass

Video games: Blizzard cancels Blizzcon 2024, its annual high mass Falling wings of the Moulin Rouge: who will pay for the repairs?

Falling wings of the Moulin Rouge: who will pay for the repairs? “You don’t sell a company like that”: Roland Lescure “annoyed” by the prospect of a sale of Biogaran

“You don’t sell a company like that”: Roland Lescure “annoyed” by the prospect of a sale of Biogaran Exhibition: in Deauville, Zao Wou-Ki, beauty in all things

Exhibition: in Deauville, Zao Wou-Ki, beauty in all things Dak’art, the most important biennial of African art, postponed due to lack of funding

Dak’art, the most important biennial of African art, postponed due to lack of funding In Deadpool and Wolverine, Ryan and Hugh Jackman explore the depths of the Marvel multiverse

In Deadpool and Wolverine, Ryan and Hugh Jackman explore the depths of the Marvel multiverse Tom Cruise returns to Paris for the filming of Mission Impossible 8

Tom Cruise returns to Paris for the filming of Mission Impossible 8 Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Basketball: Strasbourg appeals the victory recovered by Monaco

Basketball: Strasbourg appeals the victory recovered by Monaco Top 14: UBB with Tatafu and Moefana against Bayonne

Top 14: UBB with Tatafu and Moefana against Bayonne MotoGP: Bagnaia dominates qualifying practice in Spain and sets track record

MotoGP: Bagnaia dominates qualifying practice in Spain and sets track record Olympic Games: in Athens, Greece transmits the Olympic flame to France

Olympic Games: in Athens, Greece transmits the Olympic flame to France