Swedish Kullagerfabrikens state of the art digital production facility in the D-factory is to be found in the same area in Gamlestaden in Gothenburg, sweden, where the company was founded in 1907. But with the framsynte the engineer Sven Wingquist had certainly been surprised if he could see how his ground-breaking invention around the spherical bearings manufactured today.

the Difference is substantial even compared with when the production manager Ibrahim Dusi started to work at SKF in 2002.

– head Screwdriver and hammer is no longer needed, not earplugs, either, " he says smiling as he shows us around in one of the country's most high-tech manufacturing plants.

which is controlled via transmitters in the ceiling, swinging around the corner. The ”shake hands” digitally with a robot, who just completed work to assemble the hardened and ground layer and placed it on a pallet. The robot put on a skyddspapper and sends a signal to the truck, insert the fork into the pallet, and goes with the load to the next station. The layer will appear in a box, ready to be sent out to the customer.

The automated process ensures that the right thing ends up in the right place at the right time. Everything is monitored by Ibrahim Dusi and his colleagues, which has gone from being assemblers to systemkontrollanter with the mobile and portable computer as a tool. Training and up-skilling has been a part of the change.

Ibrahim Dusi and Kent Viitanen at the factory in Gothenburg. Photo: Tomas Ohlssonthe first few weeks rolling production is now above reproach. Dusi can only see advantages with the changes.

– the Quality, the traceability, the working environment, the ergonomics, everything is better. And if something goes wrong stops the entire process and we get direct information on what happened in the cell phone. This is a completely different work today, " he says.

the Robots and the trucks are working 24 hours a day without a coffee break. Only few operations are done manually, tool changes and quality assurance. To paste labels on the boxes is a bit surprising for a function that is performed by man, but the Dusi explains that this will be done automatically.

In the entire D-factory produced the 800,000 stock annually. The digital production unit, which was inaugurated in 2017, an investment of 190 million and is described by management as the industrial revolution 4.0. The automation has done to the number of employees in the factory could be reduced from 130 to over 32.

Behind the plexiglass works robots for fully. Photo: Tomas Ohlssontillverkningsansvarig within the SKF group, which makes us company on the tour, most of the near 100 people who are not needed longer been offered other jobs within the SKF group. He, too, sees only advantages with the automation and believe that it is a necessity if SKF is to be competitive in the future and maintain its position of world leadership.

" If we had not gone this route had we been less competitive in the day, but the major effect we will see in a few years. Our competitors are also working with this, but I don't think there is any ”run” so far as we have done in some of our feeds, " says Viitanen.

from a medarbetarperspektiv and yet there is a downside to that fewer are needed to produce more, but we believe that the benefits outweigh as the company increases its capacity and can do more business. He also believes that the production in the future will be increasingly able to be done at home.

Western europe is a höglöneregion, but the effect becomes less important when we make this trip. About 15 years there will not be personnel costs, which is crucial. The world will be regional and the manufacturing cost will be the same as it is for example, in China and in India, " says Viitanen, who is convinced that logistics costs come to be more and more crucial.

”It is only to be resolute and say that this is going to get personalkonsekvenser that we have to deal in different ways,” says Kent Viitanen. Photo: Tomas Ohlssonto automate many of their 100 factories around the world, today has 44.000 employees worldwide and 2.800 in Sweden. Viitanen track to the workforce in the production of 10-15 years can be halved, thanks to the automation. He explains that the company has been openly, in the face of the unions with the way you look at the development and that this is something you must manage together.

– It is only to be resolute and say that this is going to get personalkonsekvenser that we have to deal in different ways. We will need fewer people to do the same job. The option to not take that step is that we do not need any people, for we have no job or market to defend, " he says, and points out that digitisation also creates new job opportunities, both within and outside the company.

the competence shift during the change is at least as important for SKF. The employees must be given a brand-new digital profile. The company has recruited a long line of experts in automation to the global process development, but He stresses that kompetensförstärkningen must also be done locally, so that no factory will be dependent on the people in Gothenburg in order to manage your daily delivery.

When we test new technology in our factories, examines the cities with ten million inhabitants.

He believes that the digital production unit after further trimming will have 20 employees, and does not rule out that the SKF group in the future will have fully automated factories. He says that automation in itself is becoming cheaper every day, and to the nation, who today runs the strongest is China.

– When we test new technology in our factories, examines the cities with ten million inhabitants. They have seen this development and therefore we are trying to teach us of their progress, " says Viitanen.

On the factory floor to go driverless trucks around and retrieves and delivers the goods. Photo: Tomas Ohlssonare well aware of SKF's plans for the future. Zarko Djurovic is the president of the metalworkers ' union, and says that they basically look positively on the development because it secures jobs at the same time as the production stays in Sweden.

at the same time, he points out, it is necessary to develop the skills of staff to cope with the demands of other tasks, just as happened with those who left the digital production unit, and got a job in the other departments.

Djurovic says that he is met by mixed reactions among the employees.

– There are those who welcome it, there are those who wonder if they are going to handle the future jobs. They may have been working at SKF for a very long time and is worried about what will happen if everything is fully automated. So there is certainly a concern, " says Djurovic, who think that dialogue with the management of the company is good and that you have been open with future plans, and shown that you want to develop their staff.

he receives from trade union colleagues at the factories abroad.

SKF in Gothenburg is facing large retirements, which will be a way to reduce the staff naturally. Fackbasen however, doubts about management's prophecy of a halving of the number of employees in the production.

– instead of halving staffing I would like to see double productivity and new tasks. We will perhaps be less, but not 50 per cent less, " says Djurovic.

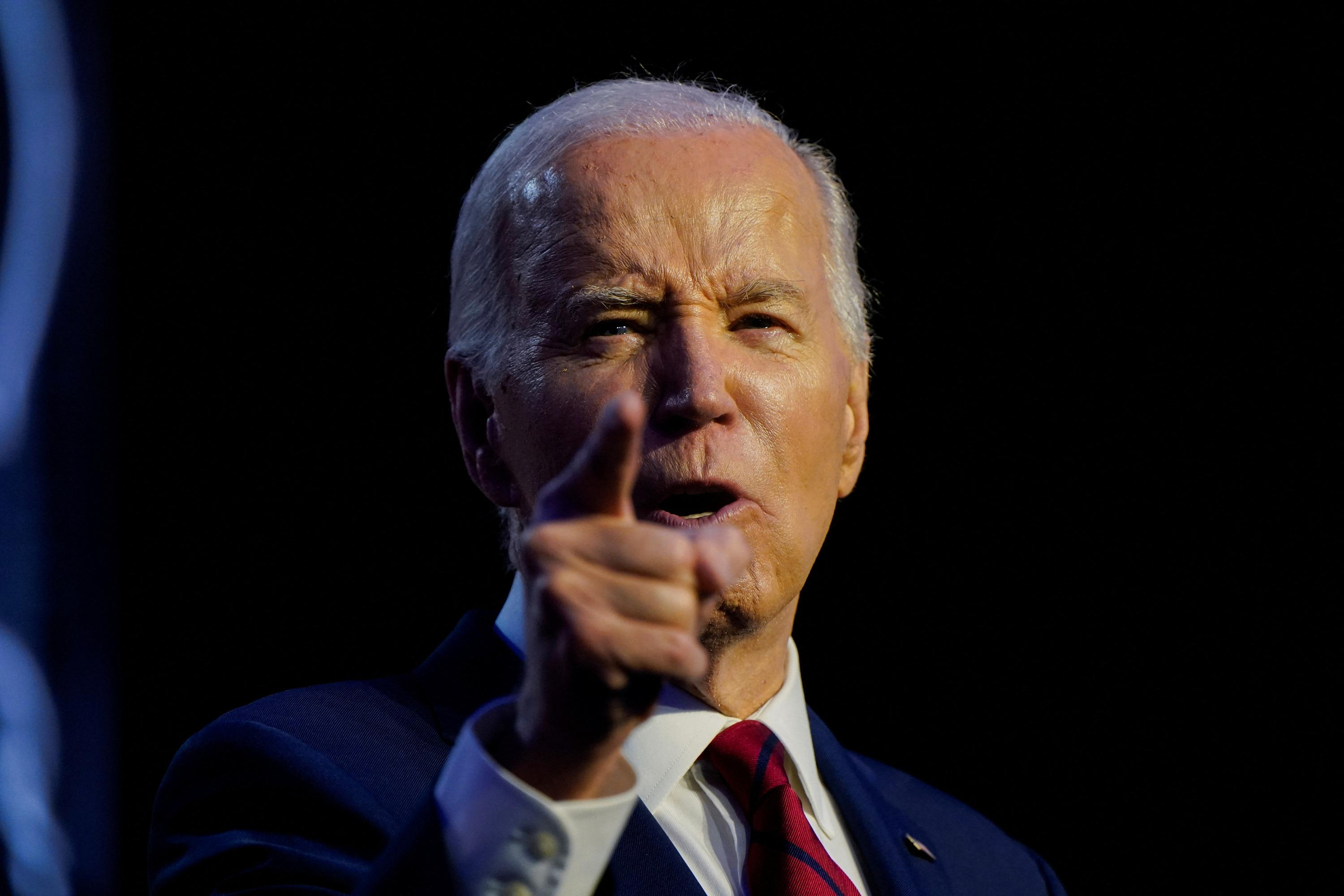

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump Maurizio Molinari: “the Scurati affair, a European injury”

Maurizio Molinari: “the Scurati affair, a European injury” Hamas-Israel war: US begins construction of pier in Gaza

Hamas-Israel war: US begins construction of pier in Gaza Israel prepares to attack Rafah

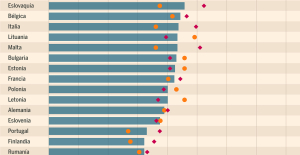

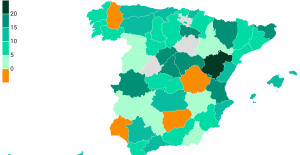

Israel prepares to attack Rafah Spain is the country in the European Union with the most overqualified workers for their jobs

Spain is the country in the European Union with the most overqualified workers for their jobs Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Colorectal cancer: what to watch out for in those under 50

Colorectal cancer: what to watch out for in those under 50 H5N1 virus: traces detected in pasteurized milk in the United States

H5N1 virus: traces detected in pasteurized milk in the United States Private clinics announce a strike with “total suspension” of their activities, including emergencies, from June 3 to 5

Private clinics announce a strike with “total suspension” of their activities, including emergencies, from June 3 to 5 The Lagardère group wants to accentuate “synergies” with Vivendi, its new owner

The Lagardère group wants to accentuate “synergies” with Vivendi, its new owner The iconic tennis video game “Top Spin” returns after 13 years of absence

The iconic tennis video game “Top Spin” returns after 13 years of absence Three Stellantis automobile factories shut down due to supplier strike

Three Stellantis automobile factories shut down due to supplier strike A pre-Roman necropolis discovered in Italy during archaeological excavations

A pre-Roman necropolis discovered in Italy during archaeological excavations Searches in Guadeloupe for an investigation into the memorial dedicated to the history of slavery

Searches in Guadeloupe for an investigation into the memorial dedicated to the history of slavery Aya Nakamura in Olympic form a few hours before the Flames ceremony

Aya Nakamura in Olympic form a few hours before the Flames ceremony Psychiatrist Raphaël Gaillard elected to the French Academy

Psychiatrist Raphaël Gaillard elected to the French Academy Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

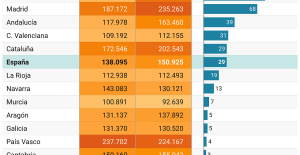

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Archery: everything you need to know about the sport

Archery: everything you need to know about the sport Handball: “We collapsed”, regrets Nikola Karabatic after PSG-Barcelona

Handball: “We collapsed”, regrets Nikola Karabatic after PSG-Barcelona Tennis: smash, drop shot, slide... Nadal's best points for his return to Madrid (video)

Tennis: smash, drop shot, slide... Nadal's best points for his return to Madrid (video) Pro D2: Biarritz wins a significant success in Agen and takes another step towards maintaining

Pro D2: Biarritz wins a significant success in Agen and takes another step towards maintaining