Thanks to the technology developed here, three Chinese factories are already using these microorganisms to convert the greenhouse gases they emit into ethanol.

Then, thanks to partnerships with major brands such as Zara or L'Oréal, this ethanol is in turn transformed into everyday products: bottles, household products, sports shorts or even dresses.

“It is clear that I would not have thought 14 years ago that we would put cocktail dresses on the market from the emissions of steel mills,” laughs Michael Köpke, who joined LanzaTech almost in its infancy. .

This company is the only American among the 15 finalists for the Earthshot prize, created by Prince William to reward initiatives in favor of the climate. The winners will be announced on Friday.

Since its launch, LanzaTech and its 200 employees claim to have avoided releasing 200,000 tons of CO2 into the atmosphere, producing instead some 190 million liters of ethanol.

A "drop of water" compared to the quantities needed to fight against climate change, concedes Michael Köpke, microbiologist.

But after having spent 15 years developing this technique and proving its feasibility on a large scale, the ambition today is to multiply the participating factories.

“We want to get to a point where we will only use the carbon already extracted from the ground, to keep it in circulation”, instead of extracting more oil and gas, explains Mr Köpke.

- "Athlete" bacteria -

LanzaTech likens its technology to designing beer: instead of fermenting sugar, the raw material here is greenhouse gases, and the end product is ethanol.

The commercial bacterium was identified decades ago in rabbit feces. The company placed it in industrial conditions to optimize its performance, "a bit like training an athlete", compares Michael Köpke.

These bacteria are then sent in the form of freeze-dried powder to the factories, which take charge of the construction of reactors several meters high where they will be dumped.

These corporate clients will then reap the rewards of the sale of ethanol.

The Chinese sites are a steel plant and two ferroalloy plants. Six other sites are under construction, including one in Belgium for an ArcelorMittal plant and another in India with the Indian Oil Company.

Since bacteria can ingest CO2, carbon monoxide or hydrogen, the process is very "flexible", more so than "any other gas conversion technology", explains Zara Summers, vice president for science at LanzaTech.

The raw material can be "garbage" that is gasified, "agricultural waste, or the gases released by any heavy industry", she explains.

The various partnerships established have already made it possible to create, from these gases, household products sold on the shelves of the large supermarket chain Migros, or even two collections of dresses for Zara.

Sold around 90 dollars, they are made with polyester from 20% of captured gases.

According to Ms Summers, humanity "will always need carbon", but "in the future, the idea is that it will no longer be lost. (...) Instead of releasing it into the atmosphere, let's -it in products."

- Sustainable fuel -

LanzaTech has also founded a separate company, Lanzajet, to use the generated ethanol as aviation fuel ("sustainable aviation fuel", SAF). Increasing the global production of sustainable fuel is a huge challenge for this sector, which seeks to "green" itself.

The company's goal is to produce nearly 3.8 billion cubic meters of fuel per year by 2030.

Unlike bioethanol produced from wheat, beets or corn, that from gas does not take the place of crops.

For LanzaTech, the next challenge is to commercialize bacteria that produce products other than ethanol. Thousands of different strains are thus tested in its laboratories.

“We have already shown that we can produce more than 100 chemicals,” explains Michael Köpke.

He is particularly enthusiastic about the idea, still under development, of being able to transform gases directly into ethylene, "the most widely used chemical product in the world" (for bottles, packaging, etc.), the production of which today generates today "almost as much" CO2 as aviation.

Currently, LanzaTech's ethanol has to be processed into polyethylene, but this step could be skipped - and save even more energy.

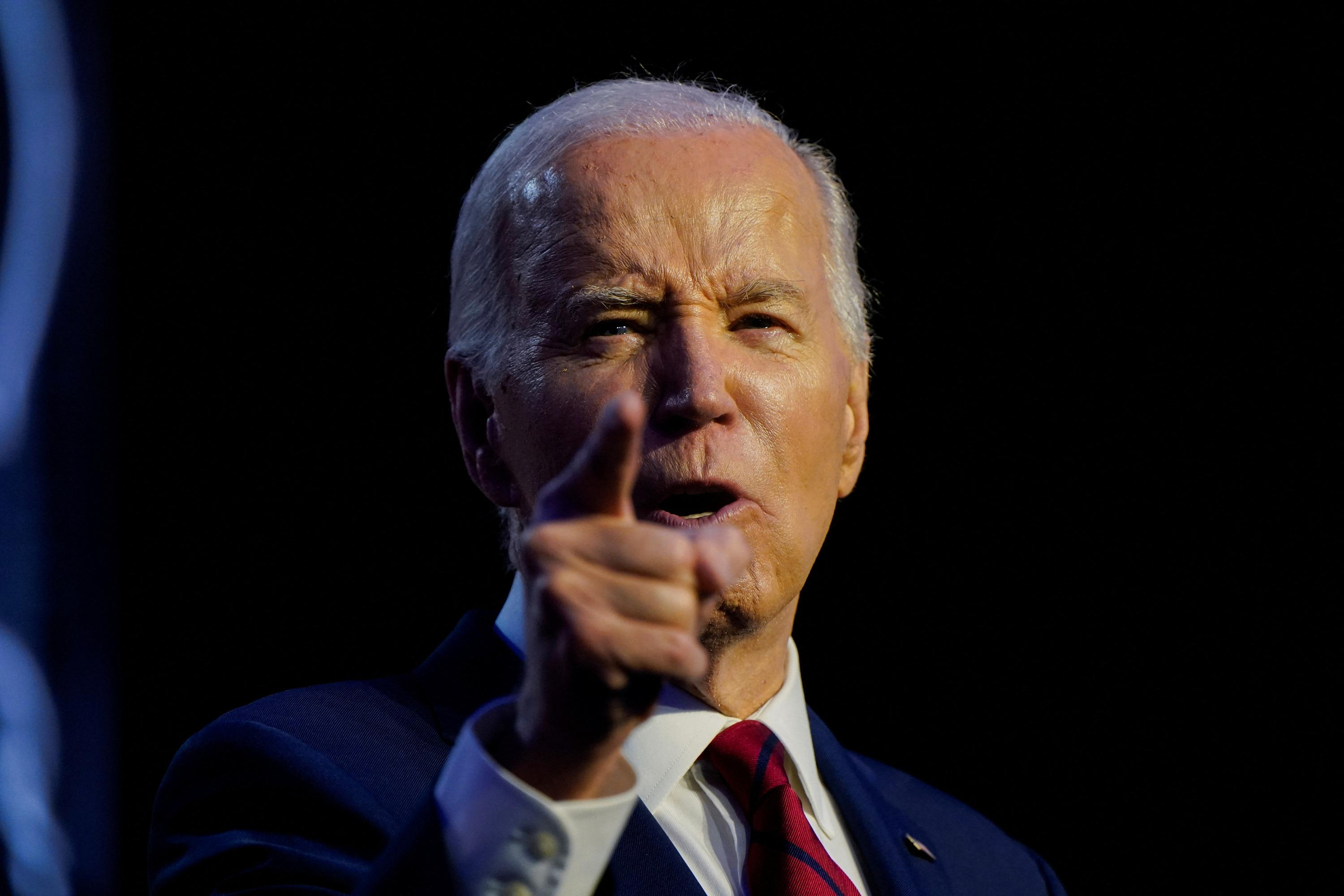

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump Maurizio Molinari: “the Scurati affair, a European injury”

Maurizio Molinari: “the Scurati affair, a European injury” Hamas-Israel war: US begins construction of pier in Gaza

Hamas-Israel war: US begins construction of pier in Gaza Israel prepares to attack Rafah

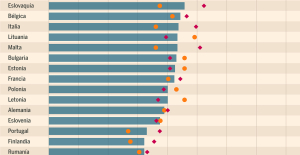

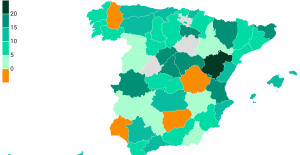

Israel prepares to attack Rafah Spain is the country in the European Union with the most overqualified workers for their jobs

Spain is the country in the European Union with the most overqualified workers for their jobs Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Colorectal cancer: what to watch out for in those under 50

Colorectal cancer: what to watch out for in those under 50 H5N1 virus: traces detected in pasteurized milk in the United States

H5N1 virus: traces detected in pasteurized milk in the United States Private clinics announce a strike with “total suspension” of their activities, including emergencies, from June 3 to 5

Private clinics announce a strike with “total suspension” of their activities, including emergencies, from June 3 to 5 The Lagardère group wants to accentuate “synergies” with Vivendi, its new owner

The Lagardère group wants to accentuate “synergies” with Vivendi, its new owner The iconic tennis video game “Top Spin” returns after 13 years of absence

The iconic tennis video game “Top Spin” returns after 13 years of absence Three Stellantis automobile factories shut down due to supplier strike

Three Stellantis automobile factories shut down due to supplier strike A pre-Roman necropolis discovered in Italy during archaeological excavations

A pre-Roman necropolis discovered in Italy during archaeological excavations Searches in Guadeloupe for an investigation into the memorial dedicated to the history of slavery

Searches in Guadeloupe for an investigation into the memorial dedicated to the history of slavery Aya Nakamura in Olympic form a few hours before the Flames ceremony

Aya Nakamura in Olympic form a few hours before the Flames ceremony Psychiatrist Raphaël Gaillard elected to the French Academy

Psychiatrist Raphaël Gaillard elected to the French Academy Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

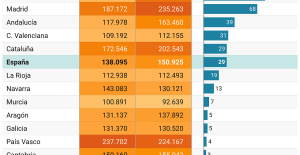

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Archery: everything you need to know about the sport

Archery: everything you need to know about the sport Handball: “We collapsed”, regrets Nikola Karabatic after PSG-Barcelona

Handball: “We collapsed”, regrets Nikola Karabatic after PSG-Barcelona Tennis: smash, drop shot, slide... Nadal's best points for his return to Madrid (video)

Tennis: smash, drop shot, slide... Nadal's best points for his return to Madrid (video) Pro D2: Biarritz wins a significant success in Agen and takes another step towards maintaining

Pro D2: Biarritz wins a significant success in Agen and takes another step towards maintaining