When the pandemic began in 2020, Airbus cut its civil aircraft production to 60 percent. As part of the "Odyssey" rationalization program, the group cut 2,300 full-time jobs in Germany, around 1,000 of them in Hamburg. The world's leading manufacturer of civil aircraft has been changing course since last year.

In 2022, 13,000 new employees were hired worldwide, and this year there should be just as many again, said Marco Wagner, labor director and head of human resources at Airbus Commercial, the civil aircraft division of the group in Germany. 3,500 of these new jobs are in the civil and military business in Germany. For the largest German location in Hamburg-Finkenwerder, Airbus is currently planning to hire 1,300 new staff this year.

Airbus is massively increasing its production in order to be able to cope with the order backlog of currently 7239 civil aircraft. This did not happen last year. Instead of the planned 720 jets, Airbus only delivered 661 machines to its customers. In Germany in particular, Airbus has a problem with the supply of qualified applicants: "It's getting tighter and more difficult, we're receiving fewer applications per position than before," said Wagner. “Germany has developed into an applicant market. The work-life balance is more important to applicants than it used to be.”

The number of suitable candidates for the aircraft construction is scarce overall - and Airbus has to share it with its suppliers, many of whom are based around the assembly plants. "We fish in the same pond as the entire value chain on which we depend," said Wagner. "It's a very fragile balance."

Parallel to the growing need for personnel for higher production, the baby boomer cohorts are retiring from working life. In civil aircraft construction alone in Northern Germany, around 500 Airbus employees leave the company each year to retire. Airbus advertises for new employees on all channels. The group needs a mixture of experienced specialists from trade and industry and newcomers who can be specially trained for the products of the future.

This applies in particular to the manufacture of aircraft with new lightweight materials and to "climate-neutral" flying. From the coming decade, Airbus intends to build production aircraft powered by hydrogen, either by direct combustion in the turbines or by electric propulsion powered by hydrogen fuel cells. "Those who come to us now can do pioneering work in the decarbonization of flying," said Wagner, especially with regard to younger employees. In the past year alone, a record number of 600 trainees and dual students were hired in Germany, and the number is set to increase even more in the coming years.

Airbus currently employs 134,000 people worldwide in its civil aircraft construction, military aircraft and missile technology and helicopter manufacturing divisions. Around 45,000 people work for Airbus in Germany. The permanent workforce in Hamburg-Finkenwerder currently comprises around 15,000 employees, and by the end of the year it could increase to around 16,000, including those who are leaving, Wagner said. In addition, there are currently around 2,000 temporary workers in Hamburg.

According to Wagner, of the 3,500 new hires planned for this year, around 1,900 will be in civil aircraft construction, 1,100 in defense business and 500 in helicopter manufacturing. Civil aircraft construction in particular is concentrated in northern Germany, in addition to Hamburg, above all in the Stade, Varel and Nordenham plants. The Bremen site, in turn, focuses primarily on defense technologies and the Ariane rocket program.

Airbus has pressure especially on its most important aircraft of the A320 model series. This ranges from the smaller A319 to the A320 to the A321. The A321 is also scheduled to come onto the market in 2024 in a new long-haul version as the A321XLR. Until the start of the pandemic in early 2020, Airbus delivered around 60 A319, A320 and A321 aircraft in their various variants every month. In 2020, production was reduced to 40 machines per month, currently it comprises around 50 jets per month. By 2025, the so-called "rate" at Airbus for the production of the A-320 family is to increase to 75 machines per month. More than half of these machines are finally assembled in Hamburg.

Wagner said it was a "good and right decision" to shut down production of everything in the A320 family at the start of the pandemic. No one could have known at the time how quickly demand would increase again. “The core decision for us was to continue production at a level of 60 percent so that our supply chain does not break down. Because many of our supplier companies would probably not have survived.”

Airbus explains the sharp rise in demand for passenger aircraft primarily through the need to replace them in view of the sharp rise in energy prices and stricter rules on climate protection: new aircraft consume significantly less kerosene and emit significantly less greenhouse gas carbon dioxide.

"Everything on shares" is the daily stock exchange shot from the WELT business editorial team. Every morning from 7 a.m. with our financial journalists. For stock market experts and beginners. Subscribe to the podcast on Spotify, Apple Podcast, Amazon Music and Deezer. Or directly via RSS feed.

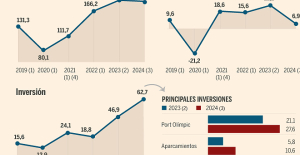

B:SM will break its investment record this year with 62 million euros

B:SM will break its investment record this year with 62 million euros War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump Maurizio Molinari: “the Scurati affair, a European injury”

Maurizio Molinari: “the Scurati affair, a European injury” Irritable bowel syndrome: the effectiveness of low-carbohydrate diets is confirmed

Irritable bowel syndrome: the effectiveness of low-carbohydrate diets is confirmed Beware of the three main sources of poisoning in children

Beware of the three main sources of poisoning in children First three cases of “native” cholera confirmed in Mayotte

First three cases of “native” cholera confirmed in Mayotte Meningitis: compulsory vaccination for babies will be extended in 2025

Meningitis: compulsory vaccination for babies will be extended in 2025 Thanks to intelligent cameras, RATP will indicate the least crowded trains on line 14

Thanks to intelligent cameras, RATP will indicate the least crowded trains on line 14 Dubai begins the transformation of Al-Maktoum to make it the future “largest airport in the world”

Dubai begins the transformation of Al-Maktoum to make it the future “largest airport in the world” When traveling abroad, money is a source of stress for seven out of ten French people

When traveling abroad, money is a source of stress for seven out of ten French people Elon Musk arrives in China to negotiate data transfer and deployment of Tesla autopilot

Elon Musk arrives in China to negotiate data transfer and deployment of Tesla autopilot Two people arrested for attempted damage to classified property at the Musée d’Orsay

Two people arrested for attempted damage to classified property at the Musée d’Orsay Death of composer Jean Musy, at 76, author of the music of Papy fait de la resistance, Les Champs-Élysées

Death of composer Jean Musy, at 76, author of the music of Papy fait de la resistance, Les Champs-Élysées Fanny Ardant prodigious in The Wound and the Thirst

Fanny Ardant prodigious in The Wound and the Thirst Hospitalized for pneumonia, Véronique Sanson cancels her concert in Nantes

Hospitalized for pneumonia, Véronique Sanson cancels her concert in Nantes Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

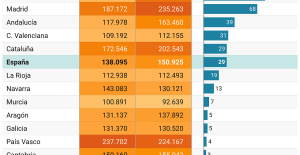

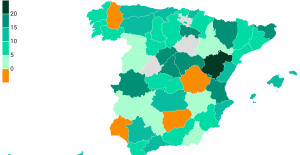

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Europeans: a senior official on the National Rally list

Europeans: a senior official on the National Rally list Blockade of Sciences Po: the right denounces a “drift”, the government charges the rebels

Blockade of Sciences Po: the right denounces a “drift”, the government charges the rebels Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Mercato: Fonseca coach of AC Milan? The Lille coach speaks

Mercato: Fonseca coach of AC Milan? The Lille coach speaks Ligue 1: OM with a three-way defense, Lens changes almost nothing

Ligue 1: OM with a three-way defense, Lens changes almost nothing Ligue 1: PSG officially crowned champion of France for the 12th time

Ligue 1: PSG officially crowned champion of France for the 12th time Ligue 1: Lyon offers Monaco and gets closer to a European place

Ligue 1: Lyon offers Monaco and gets closer to a European place