In November 2022, representatives of governments and organizations negotiated a global agreement against plastic waste for the first time in Uruguay, South America. Because while a lot has already happened in Europe when it comes to collecting and recycling recyclable materials, plastic waste remains a major problem worldwide. According to the UN, plastic pollution in the oceans and other bodies of water is actually increasing. Without countermeasures, the annual amounts could more than double from around nine to 14 million tons in 2016 to an estimated 23 to 37 million tons per year by 2040.

In view of these dangers, German researchers are working with partners from industry on methods to increase recycling rates and thus reduce CO2 emissions at the same time. At RWTH Aachen University, Professor Christian Hopmann and Mauritius Schmitz, Scientific Director for Digitization, at the Institute for Plastics Processing (IKV) rely on methods to better recycle plastics with the help of artificial intelligence (AI). Above all, it is about the fact that the chemical components of the “old” substances can be better read out with digital processes and processed into “new” products that are as high quality as possible.

“Plastics consumption in Germany in 2021 was around 12.5 million tons. The packaging accounts for around 30 percent,” says Hopmann. That's why it makes sense to focus on the packaging when it comes to recycling. And because so far more than 50 percent of all consumer plastic waste – i.e. that from the yellow bag – is incinerated, it is important to further expand the potential for recycling. This is exactly what a research project called the KI application hub, which will run until 2025, is about – plastic packaging for a sustainable circular economy using artificial intelligence.

"The materials that are used in packaging are generally easily mechanically recyclable," says Hopmann. This way of shredding, washing and melting the waste requires significantly less energy than chemical recycling, in which the plastic polymers are converted into their basic building blocks.

The Aachen project aims to ensure that mechanically recycled packaging plastics can be reused more precisely and with fewer losses. "One problem is that plastic waste is not sorted by type, and accordingly recycled granules always contain a proportion of impurities," says IKV Director Mauritius Schmitz. "In contrast to the processing of new goods, the composition and quality of the material varies and this poses various challenges in the processing process."

In the future, therefore, it will be necessary to think more about which materials and which design will later offer the best recycling options during the production of packaging. Then the recycling rate for packaging waste could also be increased from currently around 33 percent. If the end products based on recycled plastics should have the same quality and properties as when using new material, then production processes and systems would have to be adapted. "We have to train the machines, so to speak, and get them used to the fact that the composition and properties of the material vary," says Hopmann.

Various approaches to plastic recycling are to be tested in Aachen by 2025. Of course, they are all research projects that then have to be scaled up in the industrial sector, i.e. expanded. "Some tens of thousands of tons would then have to be moved every year so that it can also be operated economically," says Hopmann. However, the professor is convinced that German industrial companies will also carry out the implementation because a market for it is likely to emerge, not least due to the increasing recycling requirements specified by the EU.

AI processes could also support better sorting by automatically separating the materials better in the systems. In this way, a "purer material flow" would be obtained from the plant. Ideally, plastic products would be given digital passports in the future. "So you can always track what the material has experienced in the course of its history," explains Hopmann.

This goes from composition to functions to the stresses to which the product was exposed. This would then make it possible to identify the use for which the recyclate could be made available again. According to Hopmann, the markings required for such a passport could be made using methods that are already widespread, such as QR and barcodes. Or via added particles in the plastic. They are not visible to the human eye. According to Hopmann, however, intelligent machines can already read them.

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump Maurizio Molinari: “the Scurati affair, a European injury”

Maurizio Molinari: “the Scurati affair, a European injury” Hamas-Israel war: US begins construction of pier in Gaza

Hamas-Israel war: US begins construction of pier in Gaza First three cases of “native” cholera confirmed in Mayotte

First three cases of “native” cholera confirmed in Mayotte Meningitis: compulsory vaccination for babies will be extended in 2025

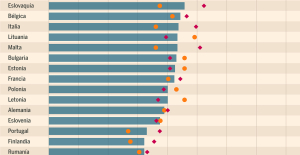

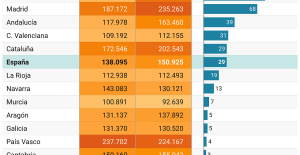

Meningitis: compulsory vaccination for babies will be extended in 2025 Spain is the country in the European Union with the most overqualified workers for their jobs

Spain is the country in the European Union with the most overqualified workers for their jobs Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Inflation rebounds in March in the United States, a few days before the Fed meeting

Inflation rebounds in March in the United States, a few days before the Fed meeting Video games: Blizzard cancels Blizzcon 2024, its annual high mass

Video games: Blizzard cancels Blizzcon 2024, its annual high mass Falling wings of the Moulin Rouge: who will pay for the repairs?

Falling wings of the Moulin Rouge: who will pay for the repairs? “You don’t sell a company like that”: Roland Lescure “annoyed” by the prospect of a sale of Biogaran

“You don’t sell a company like that”: Roland Lescure “annoyed” by the prospect of a sale of Biogaran Exhibition: in Deauville, Zao Wou-Ki, beauty in all things

Exhibition: in Deauville, Zao Wou-Ki, beauty in all things Dak’art, the most important biennial of African art, postponed due to lack of funding

Dak’art, the most important biennial of African art, postponed due to lack of funding In Deadpool and Wolverine, Ryan and Hugh Jackman explore the depths of the Marvel multiverse

In Deadpool and Wolverine, Ryan and Hugh Jackman explore the depths of the Marvel multiverse Tom Cruise returns to Paris for the filming of Mission Impossible 8

Tom Cruise returns to Paris for the filming of Mission Impossible 8 Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

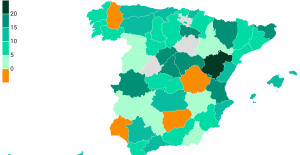

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Basketball: Strasbourg appeals the victory recovered by Monaco

Basketball: Strasbourg appeals the victory recovered by Monaco Top 14: UBB with Tatafu and Moefana against Bayonne

Top 14: UBB with Tatafu and Moefana against Bayonne MotoGP: Bagnaia dominates qualifying practice in Spain and sets track record

MotoGP: Bagnaia dominates qualifying practice in Spain and sets track record Olympic Games: in Athens, Greece transmits the Olympic flame to France

Olympic Games: in Athens, Greece transmits the Olympic flame to France