This year, 1083 launched its first 100% “made in France” jeans by growing cotton in Gers and Drôme. The manufacturer from Romans-sur-Isère sold 500 on pre-order. There will be others, but their number will depend on the quality of the next cotton harvest... Without going so far as to plant fields, dozens of brands, young and old, have bet on "made in France" : Saint-James, Petit Bateau, Le Slip français, 1083, Blanc Bonnet, Armor Lux, Aigle… Their products, to be considered as made in France, are not entirely made in the country, but “a significant part” is, according to customs.

According to the Union of Textile Industries, the sector employs 62,000 people, in 2,200 companies, small manufacturers scattered throughout France. Players who do not hesitate to go against the tide, while the general trend for fifty years has been to the relocation of clothing manufacturing in order to reduce costs as much as possible. “Those who make “made in France” are a bit crazy, determined to create local employment, minimize their carbon impact and revive territories, summarizes Guillaume Gibault, president of Slip français, which is counting on 20 million euros in turnover this year. We must revive know-how, training, innovation, recruitment…” Today, only 3% of the volumes of textiles and clothing sold in France are manufactured in France. “The fight is to increase this figure to 5% in the coming years,” according to Guillaume Gibault.

Beyond the ecological advantage, a complicated economic equation must be resolved. In a ready-to-wear market that continues to decline, consumers are more and more careful about spending. Because of inflation, he buys less and more cleverly - especially second hand. To the detriment of clothes made in France. Thus, according to a recent study by OpinionWay, 89% of French people would like to consume more products “made in France”, all categories combined. But they don't. “These products carry values. But their price is the number one obstacle to their purchase,” recognizes Gilles Lasbordes, general director of the Première Vision fashion show. However, this price will not go down. “Costs will always remain higher in France than abroad,” warns Luc Lesénécal, president of Tricots Saint James, and of the National Institute of Crafts (Inma). “Made in France” only has a future if it capitalizes on the excellence of exceptional know-how, recognized by the State label Living Heritage Company (EPV).”

Also read These provincial artisans who re-enchant the “made in France” leather bag

Saint James produces almost all of its sweaters and striped sweaters in France. In Manche, in Saint-James, 300 people work in its workshops. Three years ago, the company decided to relocate the manufacturing of its peacoats to France. Until then, woolen cloth was made in the Ardennes. But assembly was mainly done in Türkiye. The first fall-winter collection of the first “made in France” Saint James peacoats has only just been released. “We wanted our three iconic products (sweater, sailor top, pea coat) to be made in France,” explains Luc Lesénécal. We called on three makers, including one from Normandy. It costs us 30% more.” Thanks to optimization of production costs (orders are placed a year in advance), shelf prices have “only” increased by 20%.

Thomas Huriez, the founder of 1083, took ten years to relaunch the production of jeans in France, from cotton to the button. “It’s laborious, long but stimulating,” he says. Creating beautiful products locally for consumers we meet in our stores and workshops gives meaning. Economically, this difficult challenge is possible thanks to short circuits.” In a market of 67 million jeans purchased in France each year, 1083 sells 50,000. It's much more than initially imagined, but it's a drop in the bucket. “Producing in France requires strong and unique added value,” insists Céline Choain, partner at Kea.

Watch the “Made in France” video: does it work or not? - Olivier Ducatillion’s explanations

However, volumes are not taking off. The French textile industry therefore wrote to Emmanuel Marcon on November 9 to receive concrete support in its relocation to France. In addition to investment support, professionals and their representatives are asking for tax incentives such as reduced VAT or subsidies. And, why not, more public orders. Saint-James supplies, on a marginal basis, sweaters to the army, air force and the national navy. They also want to put an end to the confusion created by product labeling. Today, we find brands with French connotations and blue, white and red labels on products that are absolutely not made in France.

“There are several paid labels, such as Origine France Garantie and France Terre Textile,” explains Martin Breuvart, president of Lemahieu hosiery and Façon de faire, a collective of 180 textile manufacturers. The “made in France” label is free, but vague. We are asking the government to impose the same label on everyone, with a requirement for transparency on the manufacturing stages.”

“Teachers are there to teach facts to students”: in the United Kingdom, the government wants to backtrack on gender theory in schools

“Teachers are there to teach facts to students”: in the United Kingdom, the government wants to backtrack on gender theory in schools Construmat grows by 50% and focuses on sustainability and innovation

Construmat grows by 50% and focuses on sustainability and innovation War in Ukraine: one week later, where is the Russian offensive in Kharkiv?

War in Ukraine: one week later, where is the Russian offensive in Kharkiv? An American tourist steals a mug of beer from a tavern in Munich and admits it...50 years later

An American tourist steals a mug of beer from a tavern in Munich and admits it...50 years later Cancer: Klineo, a platform allowing patients to access new therapies

Cancer: Klineo, a platform allowing patients to access new therapies Suicide attempts and self-harm on the rise among young girls

Suicide attempts and self-harm on the rise among young girls In Europe, 10,000 people die every day from cardiovascular disease

In Europe, 10,000 people die every day from cardiovascular disease Brussels raises Spanish GDP forecasts to 2.1% and foresees a deficit of 3% in 2024

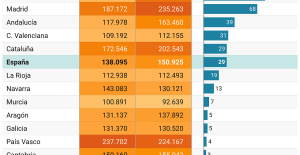

Brussels raises Spanish GDP forecasts to 2.1% and foresees a deficit of 3% in 2024 CPF: it is now much more difficult to use your account to finance your motorcycle license

CPF: it is now much more difficult to use your account to finance your motorcycle license Audible signal, hardening of the accelerator… New cars must be equipped with an “intelligent” speed limiter

Audible signal, hardening of the accelerator… New cars must be equipped with an “intelligent” speed limiter YouTube: while Tibo Inshape has just exceeded 18 million subscribers, Squeezie is making its return this Saturday

YouTube: while Tibo Inshape has just exceeded 18 million subscribers, Squeezie is making its return this Saturday Russia: court orders seizure of assets of European banks Deutsche Bank and UniCredit

Russia: court orders seizure of assets of European banks Deutsche Bank and UniCredit A Putin biopic? Yes, thanks to artificial intelligence

A Putin biopic? Yes, thanks to artificial intelligence Cannes 2024: with Emilia Pérez, Audiard delights in a new genre

Cannes 2024: with Emilia Pérez, Audiard delights in a new genre The sequel to the animated classic My Neighbor Totoro will be screened in Cannes

The sequel to the animated classic My Neighbor Totoro will be screened in Cannes An “exhausting and dangerous” journey: filmmaker Mohammad Rasoulof recounts his escape from Iran

An “exhausting and dangerous” journey: filmmaker Mohammad Rasoulof recounts his escape from Iran Omoda 7, another Chinese car that could be manufactured in Spain

Omoda 7, another Chinese car that could be manufactured in Spain BYD chooses CA Auto Bank as financial partner in Spain

BYD chooses CA Auto Bank as financial partner in Spain Tesla and Baidu sign key agreement to boost development of autonomous driving

Tesla and Baidu sign key agreement to boost development of autonomous driving Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV The home mortgage firm rises 3.8% in February and the average interest moderates to 3.33%

The home mortgage firm rises 3.8% in February and the average interest moderates to 3.33% This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Europeans: a “Free Palestine” list, whose logo advocates the disappearance of Israel, officially a candidate

Europeans: a “Free Palestine” list, whose logo advocates the disappearance of Israel, officially a candidate New Caledonia: Zemmour accuses Le Pen of “giving in to the thugs and looters”

New Caledonia: Zemmour accuses Le Pen of “giving in to the thugs and looters” Europeans: between the RN and the “euro-gagas”, the communist Léon Deffontaines dreams of breaking through to the left

Europeans: between the RN and the “euro-gagas”, the communist Léon Deffontaines dreams of breaking through to the left Europeans: professor threatened with death Didier Lemaire shows his support for François-Xavier Bellamy

Europeans: professor threatened with death Didier Lemaire shows his support for François-Xavier Bellamy These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Ligue 1: after asking his coach not to play, Danso (Lens) removed from the group

Ligue 1: after asking his coach not to play, Danso (Lens) removed from the group Ligue 1: like last year, Mostafa Mohamed does not want to wear the jersey against homophobia

Ligue 1: like last year, Mostafa Mohamed does not want to wear the jersey against homophobia Handball (F): Metz once again wins the Coupe de France

Handball (F): Metz once again wins the Coupe de France Tennis: “I love Paris, it’s a special place for me,” smiles Swiatek about Roland-Garros

Tennis: “I love Paris, it’s a special place for me,” smiles Swiatek about Roland-Garros