And another factory in Dunkirk. The city and especially the Hauts de France region continue to welcome new factories. And many are linked to the development of electric vehicles. This is again the case this time. Eramet and Suez announced this Friday their decision to set up their future electric vehicle battery recycling plant in Dunkirk. “The battery cluster is in Hauts de France,” explains Marc Ferreol, dismantling director at Suez. We chose to settle near the gigafactories currently under construction.” And there are still four planned today.

The two partners have been working on the project for several years. “Suez is a player in recycling. We offer circular solutions to both communities and manufacturers and it is in this context that we have been working with Eramet since 2019,” explains Marc Ferreol. Eramet is a mining and metallurgical player. “It is very important to guarantee responsible use of our metals, and to be able to recover them at the end of their life,” explains Julien Masson, director of strategy at Eramet. This is why we have developed into metals for electric vehicles, mainly nickel and lithium.”

He had all the more reason to embark on this field as he mastered the technical skills in hydrometallurgy which made this possible. Eramet first carried out tests in its R center

“The first unit will discharge the battery then separate and sort ferrous and non-ferrous metals, plastics and other solvents,” explains Marc Ferreol. In order to produce “black mass”, a powder which contains rare metals. This first factory will be the first to be operational, in 2025. “We have just submitted the building permit application and the operating authorization request,” explains Marc Ferreol. The second unit will take the “black mass”, then, through different successive stages, collect the nickel, manganese, cobalt and lithium it contains. “We are a little out of phase compared to upstream, since we will make the final investment decision at the end of 2024,” specifies Julien Masson. It should then be operational in 2027. “We will support car manufacturers who must reach 65% recycling by 2025: this is why we decided to accelerate the first phase,” explains Marc Ferreol.

Also read What if electric cars were smaller to save lithium?

Both partners are convinced of the potential of this market. The factory will be capable of dismantling 200,000 batteries per year, which allows it to target a European catchment area. However, all the details have not yet been fixed, in particular the exact legal framework of this cooperation. Likewise, the two groups have not yet communicated on the total amount of the investment, nor on the number of jobs created. “We obtained a subsidy of 80 million euros, including more than 60 million from the European Union, for this entire project,” explains Julien Masson. This makes it possible to envisage a total investment amounting to hundreds of millions of euros…

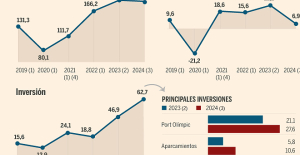

B:SM will break its investment record this year with 62 million euros

B:SM will break its investment record this year with 62 million euros War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives

War in Ukraine: when kyiv attacks Russia with inflatable balloons loaded with explosives United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump

United States: divided on the question of presidential immunity, the Supreme Court offers respite to Trump Maurizio Molinari: “the Scurati affair, a European injury”

Maurizio Molinari: “the Scurati affair, a European injury” First three cases of “native” cholera confirmed in Mayotte

First three cases of “native” cholera confirmed in Mayotte Meningitis: compulsory vaccination for babies will be extended in 2025

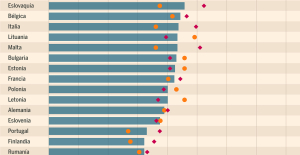

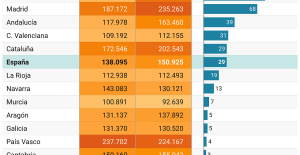

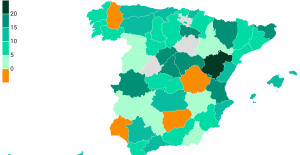

Meningitis: compulsory vaccination for babies will be extended in 2025 Spain is the country in the European Union with the most overqualified workers for their jobs

Spain is the country in the European Union with the most overqualified workers for their jobs Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 The A13 motorway will not reopen on May 1

The A13 motorway will not reopen on May 1 More than 1,500 items for less than 1 euro: the Dutch discounter Action opens a third store in Paris

More than 1,500 items for less than 1 euro: the Dutch discounter Action opens a third store in Paris 100 million euros in loans, water storage, Ecophyto plan… New measures from the executive towards farmers

100 million euros in loans, water storage, Ecophyto plan… New measures from the executive towards farmers “He is greatly responsible”: Philippe Martinez accuses Emmanuel Macron of having raised the RN

“He is greatly responsible”: Philippe Martinez accuses Emmanuel Macron of having raised the RN Les Galons de la BD dedicates War Photographers, a virtuoso album on the Spanish War

Les Galons de la BD dedicates War Photographers, a virtuoso album on the Spanish War Theater: Kevin, or the example of an academic failure

Theater: Kevin, or the example of an academic failure The eye of the INA: Jean Carmet, the thirst for life of a great actor

The eye of the INA: Jean Carmet, the thirst for life of a great actor The Nuc plus ultra: St Vincent the Texane and Neil Young the return

The Nuc plus ultra: St Vincent the Texane and Neil Young the return Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon

Even on a mission for NATO, the Charles-de-Gaulle remains under French control, Lecornu responds to Mélenchon “Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne

“Deadly Europe”, “economic decline”, immigration… What to remember from Emmanuel Macron’s speech at the Sorbonne Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Paris 2024 Olympic Games: “It’s up to us to continue to honor what the Games are,” announces Estanguet

Paris 2024 Olympic Games: “It’s up to us to continue to honor what the Games are,” announces Estanguet MotoGP: Marc Marquez takes pole position in Spain

MotoGP: Marc Marquez takes pole position in Spain Ligue 1: Brest wants to play the European Cup at the Stade Francis-Le Blé

Ligue 1: Brest wants to play the European Cup at the Stade Francis-Le Blé Tennis: Tsitsipas released as soon as he entered the competition in Madrid

Tennis: Tsitsipas released as soon as he entered the competition in Madrid