The touchscreen of the future, probably, you will be able to roll up and keep in your pocket or under your arm, just as if it were a daily paper. To afford it is a new technology just developed by experts from Rmit University, who have managed to zoom out (further) the thin film used in the screens of smartphones and tablets, making it impalpable and soft as a sheet of paper, to be precise. The details of the discovery were published in the journal Nature Electronics.

The “sheets touch of a new generation, say the authors of the research, are compatible with the technology already existing, and could even be “printed” with a technique similar to that used for the paper. To create the material, scientists have tried to improve on a compound that already exists, the indium-tin-oxide, highly conductive but also very fragile: “Basically,” explains Torben Taeneke , at the head of the team that conducted the research, “we have taken an old material and we have developed it ‘from the inside’ to create a version of thinner and more flexible: not only can you fold it and torcerlo without damaging it, but you can produce a much more efficient way and economical way compared to what happens with normal touch”. The improvements do not end here: the shrinking of the material (which, in fact, has been transformed from tri - to bi-dimensional) has also made it more transparent, which means they let in more light and therefore requires less lighting – that, in cascade, imply a saving of the consumption of the battery, estimated in 10%.

What do you mean “you manage to produce so much more efficient and cost-effective”? It is soon said: the scientists argue that in order to create the new touchscreen just a piece of equipment very cheap. “Our approach,” continues Daeneke, “does not require expensive tools or specialized. You can replicate in the home kitchen, using equipment that you can buy in any store of do it yourself.” The recipe is this: the oxide of iridium-tin is heated to 200 °C, the temperature at which it becomes liquid, and then is poured onto a surface where it is deposited, creating sheets of very thin, whose microscopic structure is different from that of the material in the solid state. In the sense that it has optical and mechanical properties very best, as we said above: more flexibility, less absorption of light, the more electrical conductivity. Scientists have created and successfully tested a functioning prototype and are now awaiting approval of the patent application to bring the product to market.

The “sheets touch of a new generation, say the authors of the research, are compatible with the technology already existing, and could even be “printed” with a technique similar to that used for the paper. To create the material, scientists have tried to improve on a compound that already exists, the indium-tin-oxide, highly conductive but also very fragile: “Basically,” explains Torben Taeneke , at the head of the team that conducted the research, “we have taken an old material and we have developed it ‘from the inside’ to create a version of thinner and more flexible: not only can you fold it and torcerlo without damaging it, but you can produce a much more efficient way and economical way compared to what happens with normal touch”. The improvements do not end here: the shrinking of the material (which, in fact, has been transformed from tri - to bi-dimensional) has also made it more transparent, which means they let in more light and therefore requires less lighting – that, in cascade, imply a saving of the consumption of the battery, estimated in 10%.

What do you mean “you manage to produce so much more efficient and cost-effective”? It is soon said: the scientists argue that in order to create the new touchscreen just a piece of equipment very cheap. “Our approach,” continues Daeneke, “does not require expensive tools or specialized. You can replicate in the home kitchen, using equipment that you can buy in any store of do it yourself.” The recipe is this: the oxide of iridium-tin is heated to 200 °C, the temperature at which it becomes liquid, and then is poured onto a surface where it is deposited, creating sheets of very thin, whose microscopic structure is different from that of the material in the solid state. In the sense that it has optical and mechanical properties very best, as we said above: more flexibility, less absorption of light, the more electrical conductivity. Scientists have created and successfully tested a functioning prototype and are now awaiting approval of the patent application to bring the product to market.

"The Republic will fight always in defense of the freedom of information, to its readers and to all those who have at heart the principles of democracy and civil coexistence"

Carlo Verdelli SUBSCRIBERS TO REPUBLIC © Reproduction reserved Today on The lesson of the Emilia region. From the duel on the fear to the idea of community Stalingrad did not fall, The government will still suffer the Vote in Emilia-Romagna: from Bibbiano to the intercoms, the two months of gambling, Matteo Salvini Zingaretti: "Dialogue and responsibility. It is the line that wins”the Republic

Germany: Man armed with machete enters university library and threatens staff

Germany: Man armed with machete enters university library and threatens staff His body naturally produces alcohol, he is acquitted after a drunk driving conviction

His body naturally produces alcohol, he is acquitted after a drunk driving conviction Who is David Pecker, the first key witness in Donald Trump's trial?

Who is David Pecker, the first key witness in Donald Trump's trial? What does the law on the expulsion of migrants to Rwanda adopted by the British Parliament contain?

What does the law on the expulsion of migrants to Rwanda adopted by the British Parliament contain? Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Colorectal cancer: what to watch out for in those under 50

Colorectal cancer: what to watch out for in those under 50 H5N1 virus: traces detected in pasteurized milk in the United States

H5N1 virus: traces detected in pasteurized milk in the United States What High Blood Pressure Does to Your Body (And Why It Should Be Treated)

What High Blood Pressure Does to Your Body (And Why It Should Be Treated) Insurance: SFAM, subsidiary of Indexia, placed in compulsory liquidation

Insurance: SFAM, subsidiary of Indexia, placed in compulsory liquidation Under pressure from Brussels, TikTok deactivates the controversial mechanisms of its TikTok Lite application

Under pressure from Brussels, TikTok deactivates the controversial mechanisms of its TikTok Lite application “I can’t help but panic”: these passengers worried about incidents on Boeing

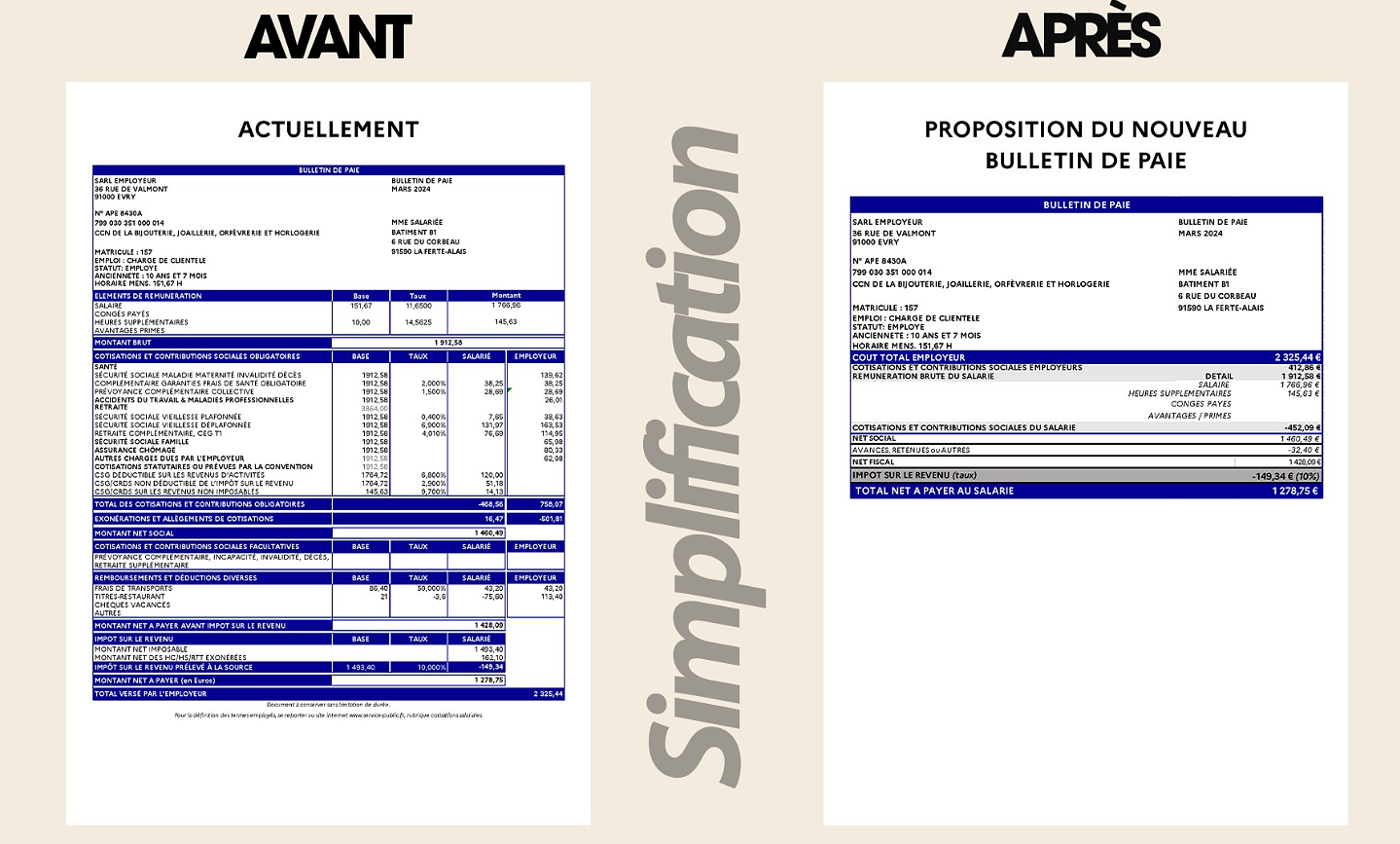

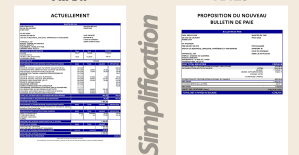

“I can’t help but panic”: these passengers worried about incidents on Boeing “I’m interested in knowing where the money that the State takes from me goes”: Bruno Le Maire’s strange pay slip sparks controversy

“I’m interested in knowing where the money that the State takes from me goes”: Bruno Le Maire’s strange pay slip sparks controversy 25 years later, the actors of Blair Witch Project are still demanding money to match the film's record profits

25 years later, the actors of Blair Witch Project are still demanding money to match the film's record profits At La Scala, Mathilde Charbonneaux is Madame M., Jacqueline Maillan

At La Scala, Mathilde Charbonneaux is Madame M., Jacqueline Maillan Deprived of Hollywood and Western music, Russia gives in to the charms of K-pop and manga

Deprived of Hollywood and Western music, Russia gives in to the charms of K-pop and manga Exhibition: Toni Grand, the incredible odyssey of a sculptural thinker

Exhibition: Toni Grand, the incredible odyssey of a sculptural thinker Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

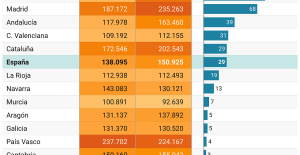

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

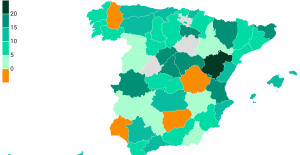

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition

With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition Europeans: the schedule of debates to follow between now and June 9

Europeans: the schedule of debates to follow between now and June 9 These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Hand: Montpellier crushes Kiel and continues to dream of the Champions League

Hand: Montpellier crushes Kiel and continues to dream of the Champions League OM-Nice: a spectacular derby, Niçois timid despite their numerical superiority...The tops and the flops

OM-Nice: a spectacular derby, Niçois timid despite their numerical superiority...The tops and the flops Tennis: 1000 matches and 10 notable encounters by Richard Gasquet

Tennis: 1000 matches and 10 notable encounters by Richard Gasquet Tennis: first victory of the season on clay for Osaka in Madrid

Tennis: first victory of the season on clay for Osaka in Madrid