40 years ago, Hamburg port companies founded the company Datenkommunikationssystem AG (Dakosy). Dakosy develops and operates software and digital platforms primarily for the Port of Hamburg, but also for the airports in Hamburg and Frankfurt. The board members Dieter Spark and Ulrich Wrage say what opportunities more digitization offers the port.

WELT AM SONNTAG: Mr Spark, Mr Wrage, you have been working on and with supply chains for decades. Did the pandemic teach you something about vulnerabilities in maritime transport that you didn't already know?

Dieter Spark: We felt confirmed in our assumption that crises are always a great opportunity for progress. In 2014 there was a situation in the port like the one at the moment and then there was a “port summit” with the then heads of HHLA and Deutsche Bahn, together with the then Economics Senator. An important consequence of this was the mandatory introduction of the so-called slot management system for hauliers at the terminals of HHLA and Eurogate, which we then developed on their behalf.

The predecessor, through which digital slots could already be pre-registered at the terminals on a voluntary basis, was only used by around ten percent of truckers. Today, everyone in Hamburg who fetches or brings containers from HHLA and Eurogate uses it. Digitized systems sometimes take a long time to establish themselves. It's always about leaving certain traditional processes behind when they are no longer up to date. Nowadays, many more trucks are handled at the Hamburg container terminals than in the past – without any traffic jams in front of the terminals.

WELT AM SONNTAG: Without the slot management system, the delays around the Hamburg container terminals would have been even worse in the past two years?

Ulrich Wrage: That is definitely the case. Nowadays you can no longer drive to a terminal to pick up a container on suspicion, but only if it is actually ready to be picked up there.

WELT AM SONNTAG: Is the port of Hamburg as digitally optimized as it could be?

Spark: I think there is still potential to further improve processes digitally. An example: It is still not possible for hauliers to combine slots in the slot management system, i.e. to say I bring a container to Burchardkai and then pick up a container from Eurogate or from an empty container depot if the truck is already in the port is under way. It is being worked on. This takes time because the companies involved have to adapt their IT systems accordingly. Basically, however, the Port of Hamburg is at the forefront when it comes to digital systems and networking overall in a northern European comparison.

WELT AM SONNTAG: What are you currently working on?

Wrage: We have just introduced an "Export Management Platform 4.0" on which you can look much further into the hinterland than before. You can use it like this, for example: If the doors are locked on an export container at BMW in Bavaria, people in Hamburg already know that this container is now on its way to the port, perhaps first on the truck, then on the train and what his estimated time of arrival will be. This allows everyone involved to plan even better.

WELT AM SONNTAG: So it's about making the transport chain more transparent.

Spark: Exactly. The transport starts way before the port. To optimize the overall system, it is important to see the movement of cargo as early as possible. A shipping company might want to load the containers of an important customer onto a specific ship and wait until the last minute for them to arrive at the port.

However, with modern technology such as the "Export Management Platform 4.0", one could have known in good time that these containers would no longer make it to the terminal before the ship departed and that other containers waiting in the port could be dispatched early. Because of this technological inefficiency, some seagoing vessels are not fully utilized today, despite extremely tight capacity.

WELT AM SONNTAG: Why not just expand the view of the transport chain?

Spark: That depends very much on the culture of the individual players, from the haulage contractor to the railway company to the transport groups and the large liner shipping companies. Sometimes there is a lack of willingness on the part of companies to pass on data about transport processes if they do not get other data directly in return. Here we can act as an intermediary with our digital platforms. In the case of the leading liner shipping companies, it is certainly the case these days that decisions about the adjustment of IT systems are more likely to be made in the company headquarters and can be influenced less than in the past by the respective national companies and their representatives.

WELT AM SONNTAG: Do you always need a fundamental consensus from your shareholders, the companies in the port industry, for major new launches?

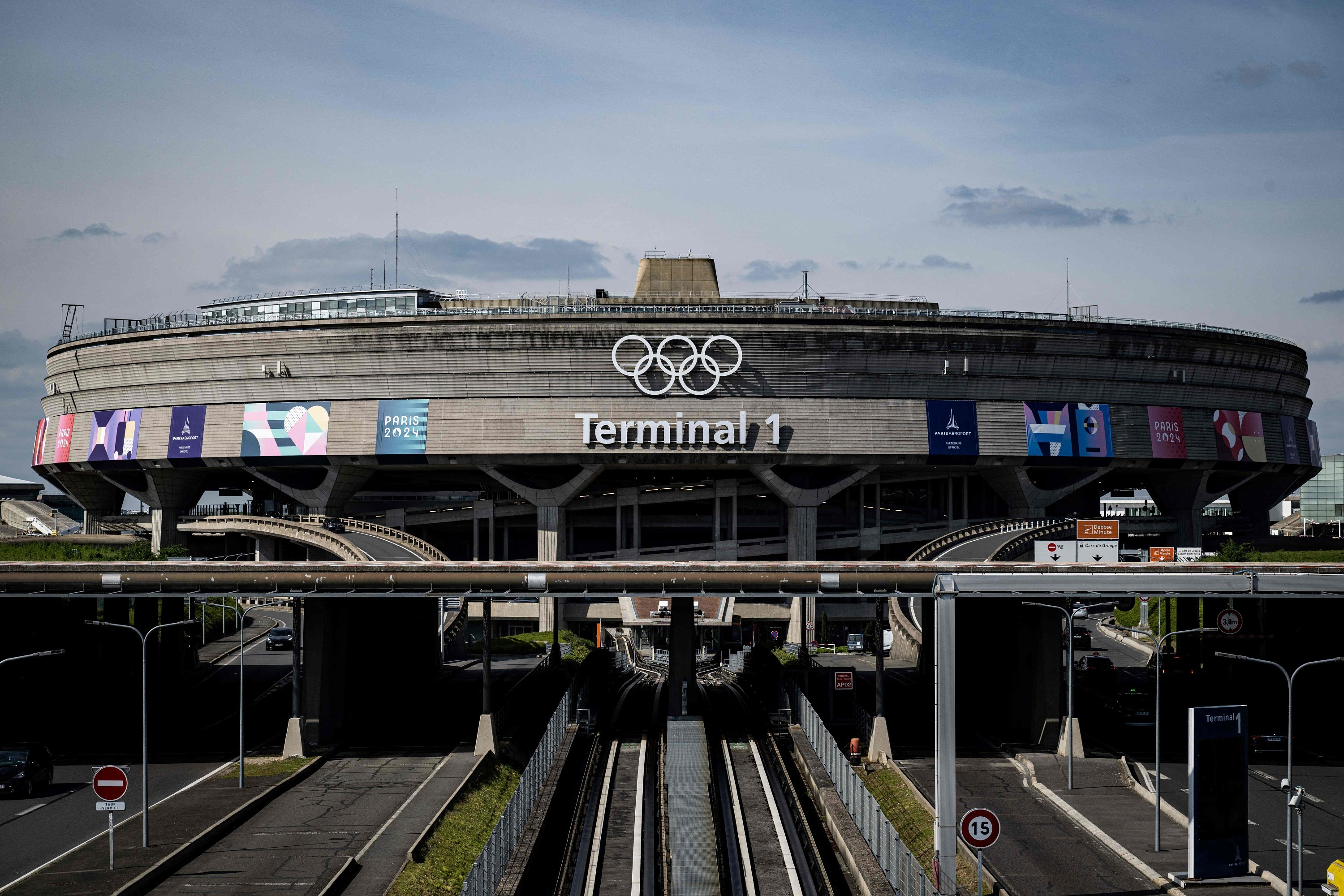

Wrage: No, we don't need that for our product developments. But the decisive factor is which companies are willing to introduce digital innovations, how and how quickly. An example: At the beginning of 2015, the Cargo Community System for air freight developed by us went into operation at the Frankfurt airport company Fraport. We have thus gone far beyond our core business, the Port of Hamburg. More than 800 companies nationwide are now connected to this system.

Spark: A surprising amount of transport data is still not processed automatically by companies. Many employees in export and import companies as well as those in the transport industry continue to access data from Internet sites with ship timetables or terminal plans with their own planning, traditionally over the phone or the same. There is still a lot of potential for simplifying, standardizing and improving transport processes. We believe that the current pressure in the transport and supply chains can also bring progress in this regard.

Wrage: For example, we developed and implemented the platform for the Hamburg Vessel Coordination Center (HVCC) on behalf of the terminals. This gives you a more detailed view of ships calling at Hamburg, for example from Gibraltar. This is a great relief for the planning in the port of Hamburg.

Spark: It used to be a value in itself that the companies involved in the transport process could exchange data digitally more easily than before. Nowadays, the added value for those involved is more in deriving new data from existing data, for example automatically including customs. This also changes the motivation of actors to participate in digital platforms.

WELT AM SONNTAG: Hapag-Lloyd wants to equip its entire container fleet with transponders and thus make its own transport system significantly more transparent and traceable overall. After all, it is about three million container units (TEU).

Wrage: This is a good example of the modernization of the transport chain. However, this data from Hapag-Lloyd is not automatically available to everyone involved in the transport chain. That then depends very much on the business model that – in this case Hapag-Lloyd – wants to connect a company with this technology. The added value of our platforms is that the current transport status of a container is made visible to all companies involved. It's not just the physical location that counts, but also whether and when the container will reach its destination according to current planning.

WELT AM SONNTAG: HHLA and Eurogate have been talking for years about a possible cooperation or even a merger of their northern German container terminals. Talks are officially on hold at the moment. In your opinion, would such a connection also result in gains in the digital efficiency of the terminals?

Spark: Yes, I think so. In particular, harmonization of terminal operating systems could have a positive impact on digital skills.

Wrage: Incidentally, we will soon also be introducing our slot management system for the hauliers at the Eurogate Container Terminal in Bremerhaven. That would then be a contribution from us to greater harmonization of the processes in the north.

The company Datenkommunikationssystem AG (Dakosy) connects more than 2000 participants in Hamburg in the handling of import and export, among others with the Hamburg Vessel Coordination Center (HVCC) of HHLA and Eurogate. Dakosy generated around 32 million euros in sales in 2021 with a total of around 280 employees. The graduate industrial engineer Dieter Spark (63) has been a member of the Dakosy board since 2002. Spark had already worked for the company as a student trainee. Also since 2002, the trained freight forwarding clerk Ulrich Wrage (55) has been on the Dakosy board.

Germany: Man armed with machete enters university library and threatens staff

Germany: Man armed with machete enters university library and threatens staff His body naturally produces alcohol, he is acquitted after a drunk driving conviction

His body naturally produces alcohol, he is acquitted after a drunk driving conviction Who is David Pecker, the first key witness in Donald Trump's trial?

Who is David Pecker, the first key witness in Donald Trump's trial? What does the law on the expulsion of migrants to Rwanda adopted by the British Parliament contain?

What does the law on the expulsion of migrants to Rwanda adopted by the British Parliament contain? Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024

Parvovirus alert, the “fifth disease” of children which has already caused the death of five babies in 2024 Colorectal cancer: what to watch out for in those under 50

Colorectal cancer: what to watch out for in those under 50 H5N1 virus: traces detected in pasteurized milk in the United States

H5N1 virus: traces detected in pasteurized milk in the United States What High Blood Pressure Does to Your Body (And Why It Should Be Treated)

What High Blood Pressure Does to Your Body (And Why It Should Be Treated) Insurance: SFAM, subsidiary of Indexia, placed in compulsory liquidation

Insurance: SFAM, subsidiary of Indexia, placed in compulsory liquidation Under pressure from Brussels, TikTok deactivates the controversial mechanisms of its TikTok Lite application

Under pressure from Brussels, TikTok deactivates the controversial mechanisms of its TikTok Lite application “I can’t help but panic”: these passengers worried about incidents on Boeing

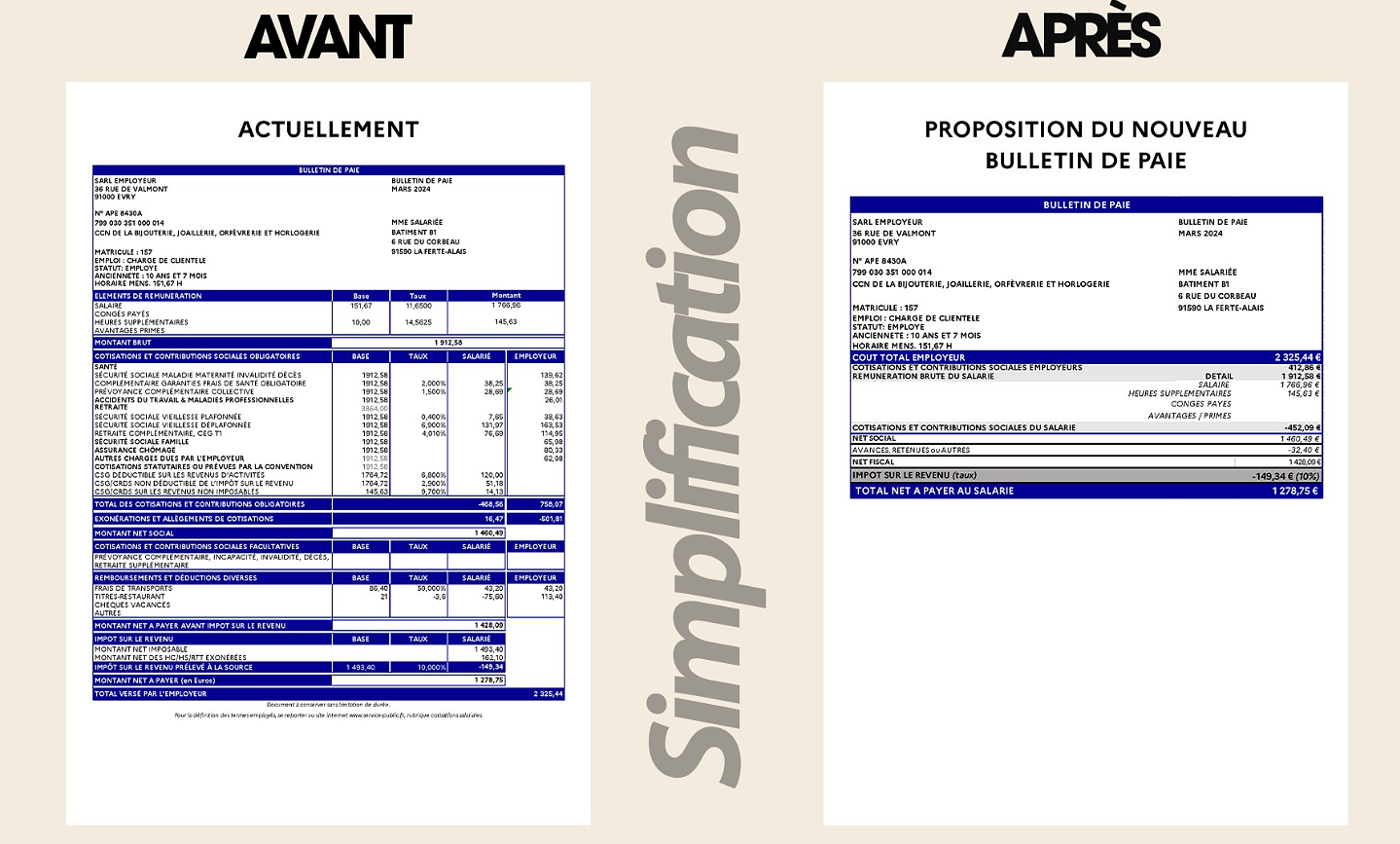

“I can’t help but panic”: these passengers worried about incidents on Boeing “I’m interested in knowing where the money that the State takes from me goes”: Bruno Le Maire’s strange pay slip sparks controversy

“I’m interested in knowing where the money that the State takes from me goes”: Bruno Le Maire’s strange pay slip sparks controversy 25 years later, the actors of Blair Witch Project are still demanding money to match the film's record profits

25 years later, the actors of Blair Witch Project are still demanding money to match the film's record profits At La Scala, Mathilde Charbonneaux is Madame M., Jacqueline Maillan

At La Scala, Mathilde Charbonneaux is Madame M., Jacqueline Maillan Deprived of Hollywood and Western music, Russia gives in to the charms of K-pop and manga

Deprived of Hollywood and Western music, Russia gives in to the charms of K-pop and manga Exhibition: Toni Grand, the incredible odyssey of a sculptural thinker

Exhibition: Toni Grand, the incredible odyssey of a sculptural thinker Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

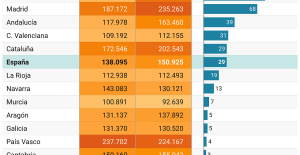

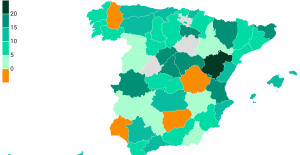

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Sale of Biogaran: The Republicans write to Emmanuel Macron

Sale of Biogaran: The Republicans write to Emmanuel Macron Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou

Europeans: “All those who claim that we don’t need Europe are liars”, criticizes Bayrou With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition

With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition Europeans: the schedule of debates to follow between now and June 9

Europeans: the schedule of debates to follow between now and June 9 These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Hand: Montpellier crushes Kiel and continues to dream of the Champions League

Hand: Montpellier crushes Kiel and continues to dream of the Champions League OM-Nice: a spectacular derby, Niçois timid despite their numerical superiority...The tops and the flops

OM-Nice: a spectacular derby, Niçois timid despite their numerical superiority...The tops and the flops Tennis: 1000 matches and 10 notable encounters by Richard Gasquet

Tennis: 1000 matches and 10 notable encounters by Richard Gasquet Tennis: first victory of the season on clay for Osaka in Madrid

Tennis: first victory of the season on clay for Osaka in Madrid