Especially in the Rhenish strongholds of the carnival, countless beers are being tapped these days - from professional dispensing systems, but also from many smaller party kegs with five or ten liters content.

Anyone who has ever tapped beer from one of these kegs knows the problem: sometimes the glass fills up almost entirely with foam and you have to wait patiently until it has turned back to beer before you can top up. And then the game repeats itself and it can take minutes to hold a glass with an acceptable fill level and not too much foam. But the opposite problem also occurs. Sometimes a glass fills up quickly, but is not crowned with a white flower.

The hobby tapper learns over time how the processes and results can be improved - first hold the glass at an angle, place the tap on the inner wall and initially not select the flow rate too high. One certainly cannot speak of an optimization in the scientific sense, but that is not the point in this case.

From the professional perspective of an innkeeper, the optimal tapping is nevertheless of great importance. On the one hand, the guest should of course be served a “perfect” beer with a nice head of foam – not too small and not too big.

And so scientists led by Wenjing Lyu from the Chinese Academy of Sciences have investigated the question of how beer tapping can be optimized. They have now published their findings, which they gained with the help of computer simulations, in the journal "Physics of Fluids".

"These model calculations are a complex task because numerous physical and chemical interactions that occur when beer is poured have to be taken into account," says Lyu. "It's about fluid mechanics, the transfer of heat and masses and also chemical reactions."

In addition, the whole thing also depends on the temperature of the beer, the pressure, the carbon dioxide concentration and the shape of the tap tip. Never before have researchers simulated this extremely complicated process on the computer.

The researchers report that their model allows them to predict the properties of the beer crown - its height, stability and the volume ratio of liquid beer and foam in the glass.

The research results cannot be implemented immediately for the hobby tapper. However, the findings can be used to optimally design taps - optimal in the sense that the greatest possible flow rate is achieved, with which a perfectly crowned beer can still be produced. In short: the new findings allow as many beers as possible to be tapped per unit of time.

And this is where the economic relevance of the research work becomes clear. The scientists have a cooperation with the startup "Einstein 1", which is developing new types of taps.

"Aha! Ten minutes of everyday knowledge" is WELT's knowledge podcast. Every Tuesday and Thursday we answer everyday questions from the field of science. Subscribe to the podcast on Spotify, Apple Podcasts, Deezer, Amazon Music, among others, or directly via RSS feed.

After 13 years of mission and seven successive leaders, the UN at an impasse in Libya

After 13 years of mission and seven successive leaders, the UN at an impasse in Libya Germany: search of AfD headquarters in Lower Saxony, amid accusations of embezzlement

Germany: search of AfD headquarters in Lower Saxony, amid accusations of embezzlement Faced with Iran, Israel plays appeasement and continues its shadow war

Faced with Iran, Israel plays appeasement and continues its shadow war Iran-Israel conflict: what we know about the events of the night after the explosions in Isfahan

Iran-Israel conflict: what we know about the events of the night after the explosions in Isfahan Sánchez condemns Iran's attack on Israel and calls for "containment" to avoid an escalation

Sánchez condemns Iran's attack on Israel and calls for "containment" to avoid an escalation China's GDP grows 5.3% in the first quarter, more than expected

China's GDP grows 5.3% in the first quarter, more than expected Alert on the return of whooping cough, a dangerous respiratory infection for babies

Alert on the return of whooping cough, a dangerous respiratory infection for babies Can relaxation, sophrology and meditation help with insomnia?

Can relaxation, sophrology and meditation help with insomnia? Vacation departures and returns: with the first crossovers, heavy traffic is expected this weekend

Vacation departures and returns: with the first crossovers, heavy traffic is expected this weekend “Têtu”, “Ideat”, “The Good Life”… The magazines of the I/O Media group resold to several buyers

“Têtu”, “Ideat”, “The Good Life”… The magazines of the I/O Media group resold to several buyers The A13 motorway closed in both directions for an “indefinite period” between Paris and Normandy

The A13 motorway closed in both directions for an “indefinite period” between Paris and Normandy The commitment to reduce taxes of 2 billion euros for households “will be kept”, assures Gabriel Attal

The commitment to reduce taxes of 2 billion euros for households “will be kept”, assures Gabriel Attal The exclusive Vespa that pays tribute to 140 years of Piaggio

The exclusive Vespa that pays tribute to 140 years of Piaggio Kingdom of the great maxi scooters: few and Kymco wants the crown of the Yamaha TMax

Kingdom of the great maxi scooters: few and Kymco wants the crown of the Yamaha TMax A complaint filed against Kanye West, accused of hitting an individual who had just attacked his wife

A complaint filed against Kanye West, accused of hitting an individual who had just attacked his wife In Béarn, a call for donations to renovate the house of Henri IV's mother

In Béarn, a call for donations to renovate the house of Henri IV's mother Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

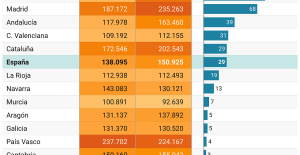

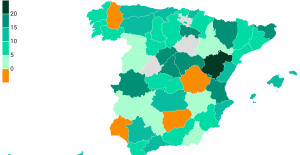

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition

With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition Europeans: the schedule of debates to follow between now and June 9

Europeans: the schedule of debates to follow between now and June 9 Europeans: “In France, there is a left and there is a right,” assures Bellamy

Europeans: “In France, there is a left and there is a right,” assures Bellamy During the night of the economy, the right points out the budgetary flaws of the macronie

During the night of the economy, the right points out the budgetary flaws of the macronie These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Rally: Neuville and Evans neck and neck after the first day in Croatia

Rally: Neuville and Evans neck and neck after the first day in Croatia Gymnastics: after Rio and Tokyo, Frenchman Samir Aït Saïd qualified for the Paris 2024 Olympics

Gymnastics: after Rio and Tokyo, Frenchman Samir Aït Saïd qualified for the Paris 2024 Olympics Top 14: in the fight for maintenance, Perpignan has the wind at its back

Top 14: in the fight for maintenance, Perpignan has the wind at its back Top 14: Toulon-Toulouse, a necessarily special reunion for Melvyn Jaminet

Top 14: Toulon-Toulouse, a necessarily special reunion for Melvyn Jaminet