The offices are empty, the employees have disappeared. Desks and chairs are standing around, some pictures and posters are still hanging on the walls. Around 200 people who previously worked in this part of the factory have moved to other buildings in the near and far vicinity. The semiconductor manufacturer Nexperia needs space in its factory on Stresemannallee in the Lokstedt district - more space and space for expanding production.

Around 1,500 people work for Nexperia in Hamburg, with almost 300 to come. “In 2021/2022 alone we are investing 110 million euros here at the site. We are massively expanding production and constantly modernizing it," says Stefan Tilger, 39, one of the two heads of Nexperia in Germany and at the same time its CFO at group level, at a presentation in one of the deserted offices.

As a location for the semiconductor industry in Germany, Hamburg is much less well known outside the industry than Dresden or Munich. But the Hanseatic city has a long history of manufacturing so-called semiconductor chips, which are indispensable for almost all electronic communication today. The Dutch company Philips once manufactured in Lokstedt. Nexperia, a subsidiary of the Chinese electronics group Wingtech, took over the factory in 2016 and has been expanding the site significantly since then.

"We are the only company in the world that focuses on the production of essential semiconductors, so to speak the basic building blocks for the semiconductor business as a whole," says Achim Kempe, 55, who manages the German business together with Tilger and who, as a member of the Management Board, is also responsible for the operative business of the group responsible.

"Here in Lokstedt, we have a capacity for manufacturing up to 100 billion semiconductors a year, which is about a quarter of global production." Nexperia currently manufactures around 15,000 different semiconductors, and around 800 new products are added every year: "There are worldwide no bigger factory than this one that produces such a large product portfolio of semiconductors from silicon.”

When you look at the yellow clinker facades of the buildings from past decades, you wouldn't think that one of the most modern factories in the world works within these walls. As an outsider, you only understand this at the security checkpoint, through which you go into the so-called clean rooms.

Employees and visitors must put on full protective suits including head and shoe coverings. In a semiconductor factory, the air is kept extremely clean, much cleaner than even in hospital operating rooms. Hair, dander and other particles can contaminate the fragile, expensive products and render them unusable.

Inside the factory, people work under a special light. For the semiconductor industry, discs with a chromium-like shine are manufactured from high-grade silicon, known as “wafers” in technical jargon. They are coated with photoresist. During processing in the factory, the structures of the future semiconductor chips are exposed onto the wafers. The corresponding rooms are therefore illuminated in yellow. This prevents the silicon wafers from being accidentally exposed.

The actual production runs fully automatically. Employees at the individual stations ensure that production runs smoothly. Using electronic microscopes, they check whether the construction plans for the semiconductors have been applied correctly. They cannot see this with the naked eye. It takes three to four weeks until a wafer with the semiconductor components on it is finished in Hamburg. It takes another week later in another, specialized factory of the group in Asia until the tiny components are detached from a wafer and encased in correspondingly small housings.

The main reason for the expansion of production in Hamburg is the switch to larger silicon wafers. "A wafer with a diameter of 200 millimeters can be used to produce around 500,000 components, which is 1.8 times as many components as from a wafer with a diameter of 150 millimeters," says Kempe.

More than a million wafers are produced in Hamburg every year, says amidst the machines Focko Meier, 46, who, as Operations Manager, manages production at the Nexperia factory in Lokstedt: "The 200-millimeter wafer is increasingly becoming the standard wafer, and the majority of our chips are already manufactured on this diameter." Nexperia uses the changeover to the larger dimensions to realign the entire processes: "We are designing our new clean rooms according to the most modern criteria and with the latest technology in a completely new design, they are designed much more generously than the previous arrangement of the production.”

Since the beginning of 2020, the pandemic and the disruption of supply chains have made it clear how dependent the European Union is on the semiconductor industry, especially in Asia, especially in China, Taiwan and South Korea. The expansion of production in Lokstedt meets the EU's goal of more than doubling the world market share of semiconductor chips manufactured in Europe to 20 percent by 2030.

Nevertheless, the semiconductor industry remains a globally extremely networked business, with a wide range of intermediate steps and supplies in production. What would happen to and within the industry if tensions between China and Taiwan continued to rise? One can only speculate about that.

"Nexperia is a subsidiary of Wingtech Technology Co., Ltd." says Stefan Tilger simply. "Our owner is not involved in the day-to-day operations of Nexperia." Hamburg's Economics Senator Michael Westhagemann (independent), who worked for the electronics companies Nixdorf and Siemens for decades, emphasizes the role of the Hanseatic city and the metropolitan region for the industry: "Production in Hamburg is of enormous importance. This applies to the supply of necessary semiconductor products, but also to securing highly qualified jobs and know-how for German and European industry.”

Nexperia, on the other hand, is pursuing ambitious goals. "Last year we generated sales of 2.1 billion US dollars, 49 percent more than in 2020. By 2030 we want to achieve annual sales of 10 billion dollars," says Tilger. On the one hand, this is served by the entry into the next size of wafers, which have a diameter of 300 millimeters - such a factory is currently being built in Shanghai by Nexperia, financed by the owner Wingtech, says Kempe.

But it is also about the production of new types of semiconductors: "With the relatively new materials silicon carbide and gallium nitride, it is possible to produce semiconductors that significantly reduce the energy consumption of energy-intensive applications compared to conventional silicon semiconductor products," says Kempe. "This will be very relevant, not least in electromobility, but also in data and server centers."

In order to expand production in Lokstedt, however, Nexperia must first increase the workforce. "We advertised 279 new positions this year, 114 of which are still open," says Tilger. "Lack of skilled workers is the big problem in our industry and the limiting factor for higher production." The EU must reform its immigration law if the semiconductor industry in Europe is to increase its production quickly: "That can only be done with highly qualified personnel, and also with people who immigrate to us in the EU.”

More employees are needed, despite the already extremely high level of automation in the manufacture of semiconductor chips. "Our factory works every day of the year, with a few shifts also over Christmas and the turn of the year," says Focko Meier at the end of the tour. "The expensive machines and systems here simply have to be operated."

Rishi Sunak wants a tobacco-free UK

Rishi Sunak wants a tobacco-free UK In Africa, the number of millionaires will boom over the next ten years

In Africa, the number of millionaires will boom over the next ten years Iran's attack on Israel: these false, misleading images spreading on social networks

Iran's attack on Israel: these false, misleading images spreading on social networks Iran-Israel: David Cameron wants the G7 to impose “coordinated sanctions” on Iran

Iran-Israel: David Cameron wants the G7 to impose “coordinated sanctions” on Iran New generation mosquito nets prove much more effective against malaria

New generation mosquito nets prove much more effective against malaria Covid-19: everything you need to know about the new vaccination campaign which is starting

Covid-19: everything you need to know about the new vaccination campaign which is starting The best laptops of the moment boast artificial intelligence

The best laptops of the moment boast artificial intelligence Amazon invests 700 million in robotizing its warehouses in Europe

Amazon invests 700 million in robotizing its warehouses in Europe Solar panels: French manufacturer Systovi announces the cessation of its activities due to “Chinese dumping”

Solar panels: French manufacturer Systovi announces the cessation of its activities due to “Chinese dumping” Tesla: canceled in court, Musk's huge compensation plan will again be submitted to shareholders

Tesla: canceled in court, Musk's huge compensation plan will again be submitted to shareholders Two, three or a hundred euros: who are the most generous customers with tips?

Two, three or a hundred euros: who are the most generous customers with tips? Boeing safety examined in US Senate, after whistleblower's revelations

Boeing safety examined in US Senate, after whistleblower's revelations Immersion among the companions of the Liberation

Immersion among the companions of the Liberation Provence-Alpes-Côte d’Azur releases several hundred thousand euros for the promotion of the work of Marcel Pagnol

Provence-Alpes-Côte d’Azur releases several hundred thousand euros for the promotion of the work of Marcel Pagnol A palm of honor distinguishes Studios Ghibli for all of their work

A palm of honor distinguishes Studios Ghibli for all of their work Gaby, a new play by Pagnol adapted into a comic strip

Gaby, a new play by Pagnol adapted into a comic strip Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

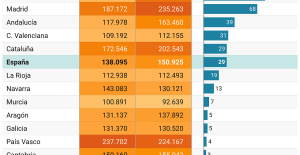

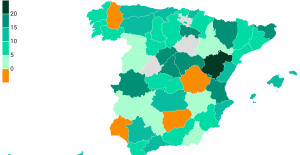

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? Europeans: the schedule of debates to follow between now and June 9

Europeans: the schedule of debates to follow between now and June 9 Europeans: “In France, there is a left and there is a right,” assures Bellamy

Europeans: “In France, there is a left and there is a right,” assures Bellamy During the night of the economy, the right points out the budgetary flaws of the macronie

During the night of the economy, the right points out the budgetary flaws of the macronie Europeans: Glucksmann denounces “Emmanuel Macron’s failure” in the face of Bardella’s success

Europeans: Glucksmann denounces “Emmanuel Macron’s failure” in the face of Bardella’s success These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Union Bordeaux Bègles-Clermont: at what time and on which channel to follow the Top 14 clash?

Union Bordeaux Bègles-Clermont: at what time and on which channel to follow the Top 14 clash? Football: Ada Hegerberg extends at OL until 2027

Football: Ada Hegerberg extends at OL until 2027 Basketball: suspended for life from NBA for fixing his match

Basketball: suspended for life from NBA for fixing his match Paris 2024 Olympic Games: boxer Estelle Mossely wants to parade on the Seine as a flag bearer

Paris 2024 Olympic Games: boxer Estelle Mossely wants to parade on the Seine as a flag bearer