The steel melt is not glowing this afternoon in the ArcelorMittal steelworks in Hamburg, production remains cold. The "Electric Arc Furnace", the heart of the steelworks, runs on electricity, and that is just too expensive. "We base our production on the short-term electricity price on the spot market," says Managing Director Uwe Braun while walking around the factory premises. "This means that the electric arc furnace is started up and shut down at short notice."

Another part of the steelworks also stands still on this day, but this has been the case for several months. In the so-called "direct reduction plant" the oxygen is extracted from the raw material iron ore. The preliminary product "sponge iron" resulting from this process is processed into steel in the electric arc furnace, either separately or in a mixture with molten steel scrap. Direct reduction works with natural gas. When its price shot up last year - a consequence of the Ukraine war - the plant was shut down. "We plan to restart the direct reduction plant earlier than we had originally planned in view of the extremely high energy prices," says Braun. “The recovery in gas prices is now making this possible. However, we will monitor further developments closely.”

A steelworks in Germany ramps up and down its production depending on the energy price – or shuts it down entirely because it is no longer economical. This is how far things have come with an industry that has been one of the pillars of German industry for two centuries. The few domestic steelworks that still exist are to be converted to “climate-neutral” production without the emission of greenhouse gases by the 2030s. The companies can hardly earn the necessary money for this at the moment

The main reason why prices rose so sharply in 2022 was that Russian natural gas was largely no longer available to supply Europe after Russia invaded Ukraine. This also drove electricity prices up in the complex energy market. "Last year, as a steel mill that relies on electricity and natural gas, we were hit incredibly hard by the crisis on the energy market," says Braun. From the group's point of view, this is particularly bitter because the ArcelorMittal site in Hamburg is one of the most modern steelworks in the world, despite being 53 years old. The plant produces only around 800 kilograms of the greenhouse gas carbon dioxide (CO2) per tonne of steel produced. This is specifically due to the use of natural gas to produce sponge iron. However, most steel mills worldwide work with coking coal in the production process. In Europe, such steelworks generate an average of 1800 kilograms of CO2 per tonne of steel.

ArcelorMittal is the world's largest steel and mining company, with crude steel production of 59 million tons in 2022. With a capacity of 1.1 million tons of steel and 700,000 tons of sponge iron per year, the Hamburg site is one of the smallest plants in the group, but it is particularly innovative. Last week, ArcelorMittal received approval from the EU Commission for federal funding of 55 million euros. In Hamburg, the group is planning a new process for the direct reduction of iron ore, which will be operated with regeneratively produced, "green" hydrogen instead of natural gas - a pioneering project for future climate-neutral steel production. Whether and when the plant will be realized is an open question. "The knowledge advantage that we have for the use of hydrogen here at the site is huge, because we have been operating a direct reduction plant with natural gas for more than 50 years," says Braun: "But the use of green hydrogen in production only makes sense then , if its use is treated preferentially in the run-up phase. For this, generation costs would have to be financially supported.”

Jesus Robles, Head of Process Technology, leads through the site into the rolling mill. Wire rod is produced there from steel billets, which in turn is the basis for a number of products, from metal grids in reinforced concrete to commercially available spax screws and guitar strings. It steams and hisses on the approximately 300-meter-long rolling train, on which the steel billets are rolled in several steps to the intended thickness, between five and 17 millimeters, depending on the product. Only a few people can be seen this afternoon. But the rolling mill is running at full production, despite the fluctuating steel production next door. In case of doubt, missing steel is bought in. The entire workforce of around 500 at the site has now come out of the short-time work of the past year - and the employees are fully paid for the usual three-shift operation.

Managing Director Braun explains in an office how the Hamburg plant should develop new perspectives from this difficult situation. "It is very difficult for us to pass on our increased costs in the highly competitive steel products market," he says. "Even the slow recovery on the market for 'low-CO2' steel, as we produce it, hasn't helped us so far." Braun is hoping for a special and relatively stable price for industrial electricity. But that can only happen with the help of the federal government. "A European industrial electricity price in Germany would definitely be a sensible element on the energy market, because other European countries such as France have long had an industrial electricity price," says Braun. "We need such an industrial electricity price that helps us to compensate for the imponderables in production."

The federal government is currently examining which economic, EU-compatible aid Germany could provide to help industry out of fossil fuels - with subsidies and tax breaks for innovative technologies, models for special depreciation, and probably also with a subsidized electricity price. “We are currently developing a concept for a national/European industrial electricity price. We want to present proposals in the first half of 2023,” says a new key issues paper by the Federal Ministry of Economics. All of these measures seem more like a planned economy than a market economy. But they are also part of an EU response to the US Inflation Reduction Act, a gigantic package of subsidies and tax breaks with which the United States hopes to overcome the consequences of the pandemic and advance climate protection. Hardly anyone has been talking about the free play of market forces for a long time.

The Hamburg Senate is watching this economic earthquake almost helplessly. The three energy-intensive metal manufacturers ArcelorMittal, Aurubis and Trimet are among the most important companies in local industry. So far. Economics Senator Melanie Leonhard (SPD) hopes that in future industry will also be able to be supplied with electricity and hydrogen from the huge potential of north German wind power. Until then, however, the works must survive. "The federal government has the homework to create the greatest possible planning security in terms of energy supply and prices with a suitable solution such as an industrial electricity price," says Leonhard. "We will actively participate in these considerations."

After 13 years of mission and seven successive leaders, the UN at an impasse in Libya

After 13 years of mission and seven successive leaders, the UN at an impasse in Libya Germany: search of AfD headquarters in Lower Saxony, amid accusations of embezzlement

Germany: search of AfD headquarters in Lower Saxony, amid accusations of embezzlement Faced with Iran, Israel plays appeasement and continues its shadow war

Faced with Iran, Israel plays appeasement and continues its shadow war Iran-Israel conflict: what we know about the events of the night after the explosions in Isfahan

Iran-Israel conflict: what we know about the events of the night after the explosions in Isfahan “Even morphine doesn’t work”: Léane, 17, victim of the adverse effects of an antibiotic

“Even morphine doesn’t work”: Léane, 17, victim of the adverse effects of an antibiotic Sánchez condemns Iran's attack on Israel and calls for "containment" to avoid an escalation

Sánchez condemns Iran's attack on Israel and calls for "containment" to avoid an escalation China's GDP grows 5.3% in the first quarter, more than expected

China's GDP grows 5.3% in the first quarter, more than expected Alert on the return of whooping cough, a dangerous respiratory infection for babies

Alert on the return of whooping cough, a dangerous respiratory infection for babies Vacation departures and returns: with the first crossovers, heavy traffic is expected this weekend

Vacation departures and returns: with the first crossovers, heavy traffic is expected this weekend “Têtu”, “Ideat”, “The Good Life”… The magazines of the I/O Media group resold to several buyers

“Têtu”, “Ideat”, “The Good Life”… The magazines of the I/O Media group resold to several buyers The A13 motorway closed in both directions for an “indefinite period” between Paris and Normandy

The A13 motorway closed in both directions for an “indefinite period” between Paris and Normandy The commitment to reduce taxes of 2 billion euros for households “will be kept”, assures Gabriel Attal

The commitment to reduce taxes of 2 billion euros for households “will be kept”, assures Gabriel Attal The exclusive Vespa that pays tribute to 140 years of Piaggio

The exclusive Vespa that pays tribute to 140 years of Piaggio Kingdom of the great maxi scooters: few and Kymco wants the crown of the Yamaha TMax

Kingdom of the great maxi scooters: few and Kymco wants the crown of the Yamaha TMax A complaint filed against Kanye West, accused of hitting an individual who had just attacked his wife

A complaint filed against Kanye West, accused of hitting an individual who had just attacked his wife In Béarn, a call for donations to renovate the house of Henri IV's mother

In Béarn, a call for donations to renovate the house of Henri IV's mother Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

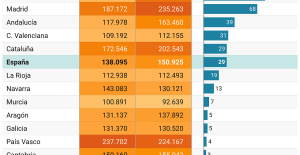

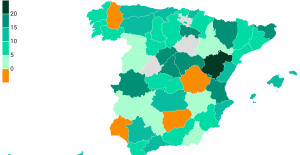

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition

With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition Europeans: the schedule of debates to follow between now and June 9

Europeans: the schedule of debates to follow between now and June 9 Europeans: “In France, there is a left and there is a right,” assures Bellamy

Europeans: “In France, there is a left and there is a right,” assures Bellamy During the night of the economy, the right points out the budgetary flaws of the macronie

During the night of the economy, the right points out the budgetary flaws of the macronie These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Formula 1: Verstappen wins the sprint in China, Hamilton 2nd

Formula 1: Verstappen wins the sprint in China, Hamilton 2nd Rally: Neuville and Evans neck and neck after the first day in Croatia

Rally: Neuville and Evans neck and neck after the first day in Croatia Gymnastics: after Rio and Tokyo, Frenchman Samir Aït Saïd qualified for the Paris 2024 Olympics

Gymnastics: after Rio and Tokyo, Frenchman Samir Aït Saïd qualified for the Paris 2024 Olympics Top 14: in the fight for maintenance, Perpignan has the wind at its back

Top 14: in the fight for maintenance, Perpignan has the wind at its back