The group suspected weeks ago that Christmas would be a difficult time for Apple. "COVID-19 restrictions are temporarily affecting the primary iPhone 14 Pro and iPhone 14 Pro Max assembly facility in Zhengzhou, China," the iPhone company reported on Nov. 6.

The plant is working with significantly reduced capacity, it said. We continue to see strong demand for the iPhone 14 Pro and iPhone 14 Pro Max models.

"However, we now expect iPhone 14 Pro and iPhone 14 Pro Max shipments to be lower than previously thought and customers will have longer wait times to receive their new products." Three weeks later, it is now clear what that is means: Apple can no longer deliver its top model before Christmas.

Anyone currently ordering an iPhone 14 Pro from the Apple Store will have to wait until December 29th. A survey by WELT among the mobile network operators Deutsche Telekom, Vodafone and Telefónica also showed that none of them can deliver before Christmas.

"Unfortunately, the delivery times are currently six to seven weeks," says Telekom. If you select your iPhone 14 Pro in the Gravis online shop, you will come across the addition "Pre-order now". And further: "The delivery will take place within the next three months after the order confirmation."

If you want to give away an iPhone 14 Pro for Christmas, you can only do so in the form of a voucher. Or just order the basic model iPhone 14, which is in stock in the Apple Stores and is often delivered the next day after an online order. But this model only has two rear cameras and last year's processor.

The reason for the delay in delivery of the Pro models is an escalation in the world's largest iPhone factory in Zhengzhou, which is operated by the contract manufacturer Foxconn. About 200,000 people work there.

Zhengzhou is the capital of the Chinese province of Henan, and the industrial complex is also known as iPhone City. According to the market researcher Counterpoint Research, around 80 percent of all iPhone 14 devices are produced in Zhengzhou, and the proportion of the Pro models is said to be even slightly higher.

After Foxconn noticed a sharp increase in corona infections in its factory and locked down the plant, the situation got out of control. Despite the ban, employees fled the site on foot for fear of infection. Photos shared on social media of workers climbing fences and walking down the street with their belongings.

Employees reported difficult conditions. They were no longer allowed to eat in the factory canteen and had to take their meals in the dormitories. There were reported complaints that not enough food was available.

Foxconn tried to persuade employees to return to the factory with higher wages and bonuses. Violent protests broke out last week, not least because employees had not received the promised pay.

Foxconn apologized with an "input error in the computer system". Videos circulating on the Weibo and Twitter platforms showed demonstrating workers encountering police officers in hazmat suits.

Over the weekend there were further protests in several Chinese cities against the strict zero-Covid policy. Hundreds of people took to the streets in Beijing and Shanghai, among other places. There were also calls for the resignation of President Xi Jinping - an extremely rare outburst of anger in China against the country's communist leadership.

There are no statements from Apple about the delivery delays. "We have members of the Apple team on site at the factory of our supplier Foxconn in Zhengzhou," it says. "We are reviewing the situation and working closely with Foxconn to ensure workers' concerns are addressed." But it's unclear when the factory will be able to resume full production capacity.

China's zero-Covid strategy is becoming an ever-increasing burden for Apple. Apple has been looking for new manufacturing sites for some time, not least because of tensions between the US and China.

But a quick turn around is not possible. However, a small part of the iPhone 14 is already being built in India, as the group announced in September.

Previously, Apple had only had older iPhone models manufactured there. But the share of Indian production will remain small for the time being. Analysts at J.P. Morgan expect around 5 percent of iPhone 14 models to be produced in the country by the end of the year. So it won't work without China.

In the past, Apple has managed to steadily increase the average selling price of its iPhones. Depending on the equipment, the latest Pro models cost between 1299 and 2099 euros in Germany.

The last three months of the year are traditionally the busiest for Apple. It is particularly inconvenient for the group not to be able to deliver its most expensive iPhone model before Christmas.

The investment house Wedbush Securities assumes that the problems in China mean a loss of sales of a billion dollars a week for Apple.

"Everything on shares" is the daily stock exchange shot from the WELT business editorial team. Every morning from 5 a.m. with the financial journalists from WELT. For stock market experts and beginners. Subscribe to the podcast on Spotify, Apple Podcast, Amazon Music and Deezer. Or directly via RSS feed.

After 13 years of mission and seven successive leaders, the UN at an impasse in Libya

After 13 years of mission and seven successive leaders, the UN at an impasse in Libya Germany: search of AfD headquarters in Lower Saxony, amid accusations of embezzlement

Germany: search of AfD headquarters in Lower Saxony, amid accusations of embezzlement Faced with Iran, Israel plays appeasement and continues its shadow war

Faced with Iran, Israel plays appeasement and continues its shadow war Iran-Israel conflict: what we know about the events of the night after the explosions in Isfahan

Iran-Israel conflict: what we know about the events of the night after the explosions in Isfahan Sánchez condemns Iran's attack on Israel and calls for "containment" to avoid an escalation

Sánchez condemns Iran's attack on Israel and calls for "containment" to avoid an escalation China's GDP grows 5.3% in the first quarter, more than expected

China's GDP grows 5.3% in the first quarter, more than expected Alert on the return of whooping cough, a dangerous respiratory infection for babies

Alert on the return of whooping cough, a dangerous respiratory infection for babies Can relaxation, sophrology and meditation help with insomnia?

Can relaxation, sophrology and meditation help with insomnia? Vacation departures and returns: with the first crossovers, heavy traffic is expected this weekend

Vacation departures and returns: with the first crossovers, heavy traffic is expected this weekend “Têtu”, “Ideat”, “The Good Life”… The magazines of the I/O Media group resold to several buyers

“Têtu”, “Ideat”, “The Good Life”… The magazines of the I/O Media group resold to several buyers The A13 motorway closed in both directions for an “indefinite period” between Paris and Normandy

The A13 motorway closed in both directions for an “indefinite period” between Paris and Normandy The commitment to reduce taxes of 2 billion euros for households “will be kept”, assures Gabriel Attal

The commitment to reduce taxes of 2 billion euros for households “will be kept”, assures Gabriel Attal The exclusive Vespa that pays tribute to 140 years of Piaggio

The exclusive Vespa that pays tribute to 140 years of Piaggio Kingdom of the great maxi scooters: few and Kymco wants the crown of the Yamaha TMax

Kingdom of the great maxi scooters: few and Kymco wants the crown of the Yamaha TMax A complaint filed against Kanye West, accused of hitting an individual who had just attacked his wife

A complaint filed against Kanye West, accused of hitting an individual who had just attacked his wife In Béarn, a call for donations to renovate the house of Henri IV's mother

In Béarn, a call for donations to renovate the house of Henri IV's mother Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV

Skoda Kodiaq 2024: a 'beast' plug-in hybrid SUV Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price"

Tesla launches a new Model Y with 600 km of autonomy at a "more accessible price" The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter

The 10 best-selling cars in March 2024 in Spain: sales fall due to Easter A private jet company buys more than 100 flying cars

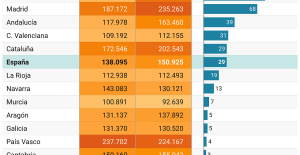

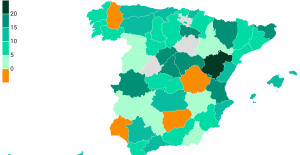

A private jet company buys more than 100 flying cars This is how housing prices have changed in Spain in the last decade

This is how housing prices have changed in Spain in the last decade The home mortgage firm drops 10% in January and interest soars to 3.46%

The home mortgage firm drops 10% in January and interest soars to 3.46% The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella

The jewel of the Rocío de Nagüeles urbanization: a dream villa in Marbella Rental prices grow by 7.3% in February: where does it go up and where does it go down?

Rental prices grow by 7.3% in February: where does it go up and where does it go down? With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition

With the promise of a “real burst of authority”, Gabriel Attal provokes the ire of the opposition Europeans: the schedule of debates to follow between now and June 9

Europeans: the schedule of debates to follow between now and June 9 Europeans: “In France, there is a left and there is a right,” assures Bellamy

Europeans: “In France, there is a left and there is a right,” assures Bellamy During the night of the economy, the right points out the budgetary flaws of the macronie

During the night of the economy, the right points out the budgetary flaws of the macronie These French cities that will boycott the World Cup in Qatar

These French cities that will boycott the World Cup in Qatar Rally: Neuville and Evans neck and neck after the first day in Croatia

Rally: Neuville and Evans neck and neck after the first day in Croatia Gymnastics: after Rio and Tokyo, Frenchman Samir Aït Saïd qualified for the Paris 2024 Olympics

Gymnastics: after Rio and Tokyo, Frenchman Samir Aït Saïd qualified for the Paris 2024 Olympics Top 14: in the fight for maintenance, Perpignan has the wind at its back

Top 14: in the fight for maintenance, Perpignan has the wind at its back Top 14: Toulon-Toulouse, a necessarily special reunion for Melvyn Jaminet

Top 14: Toulon-Toulouse, a necessarily special reunion for Melvyn Jaminet